Rottler F9A Boring Bar and Sleeving Machine: Precision and Efficiency for Engine Cylinder Restoration

The Ultimate Solution for Engine Cylinder Boring and Sleeving

Are you in search of a reliable and high-performance machine for engine cylinder boring and sleeving? Look no further than the Rottler F9A Boring Bar and Sleeving Machine. With its exceptional precision, efficiency, and innovative features, the F9A is designed to meet the demands of professional engine builders, automotive enthusiasts, and machining shops.

Unparalleled Precision and Versatility

The F9A Boring Bar and Sleeving Machine is engineered to deliver unparalleled precision in engine cylinder restoration. Whether you need to bore, sleeve, or repair engine cylinders, this versatile machine can handle it all. Its advanced design ensures accurate and consistent results, enabling you to achieve optimal performance and efficiency.

Advanced Features for Superior Performance

Equipped with cutting-edge technology, the F9A sets a new standard for cylinder boring and sleeving machines. Its innovative features include [mention specific features based on the machine’s capabilities and unique selling points]. These features enhance the machine’s performance, streamline operations, and improve overall productivity.

Engineered for Efficiency and Ease of Use

We understand that time is valuable in any engine machining process. The Rottler F9A is engineered with efficiency in mind, enabling faster setup, precise machining, and reduced downtime. Its user-friendly interface and intuitive controls make it easy for operators to navigate and operate the machine, even for complex tasks.

Unmatched Durability and Reliability

When investing in a machine for engine cylinder boring and sleeving, durability and reliability are paramount. The Rottler F9A is built to last, with robust construction and high-quality components that withstand the rigors of heavy usage. Count on the F9A to deliver consistent performance, day in and day out, ensuring your operations run smoothly without interruptions.

The Rottler Advantage

Choosing the Rottler F9A Boring Bar and Sleeving Machine means you benefit from Rottler’s decades of experience and expertise in the machining industry. Rottler has a proven track record of delivering cutting-edge solutions that meet the evolving needs of engine builders worldwide. With our commitment to innovation, precision, and customer satisfaction, we are your trusted partner for all your engine machining requirements.

Contact Us Today

Discover the power and performance of the F9A Boring Bar and Sleeving Machine. Visit our website at [insert website URL] to learn more about the F9A and explore its features and specifications. Contact our knowledgeable team to discuss how the F9A can elevate your engine machining capabilities. Trust Rottler for exceptional quality, reliability, and results in the world of engine cylinder boring and sleeving.

We have more then 100 years of experience

We have more then 100 years of experience

Features

- Speed – All FA boring bars have the same high performance AC servo motor. Independent feed control allows you to change the feed rate from .001″ (.025mm) to .012″ (.3mm) per revolution.

- Accuracy – The FA series boring bar uses a precision ground ball screw to control feed rate and cutter position. This allows the machines to repeat cutter position accuracy to .0002″ (.005mm).

- Strength – The Rottler proven spindle and bearing design gives you a rigid machine capable of making heavy sleeve cuts for a lifetime. The F9A spindle has been reduced to allow the machining of compact engines such as motorcycles, marine blocks and others.

- Flexibility – With variable feed rates you are able to maximize the performance of the machine. Increase spindle feed rates for simple oversize bores. Decrease feed rates for sleeve cuts or counter bores. The F9A machines can bore from 1.5″ (38mm) to 5″ (127mm). Special carbide tools are available for counterboring, chamfer cutting, offset boring, and O-ringing.

- Reliability – The F Series machines use a high-speed, cogged belt drive system. This and the use of two independent motors to run the spindle speed and feed, entirely eliminates the gear box.

- Cost Savings – The high speed Rottler FA boring bar series machine can bore a block in half the time that other boring machines require. New insert technology is producing long lasting, inexpensive inserts which are capable of handling these high speed and feed rates, with the same cost per insert as previous styles. Inserts do not require sharpening and the low cost of these tools makes them the ultimate choice for boring cylinders.

Machine Operations

- Boring & Sleeving

- Cylinder Boring

- Multi Purpose CNC (Custom Parts)

Rottler F9A Standard Equipment

Standard equipment that comes with the Rottler F9H Boring Bar and Sleeving Machine:

- Block Clamp Arm – set of 2 (Part# 502-1-30)

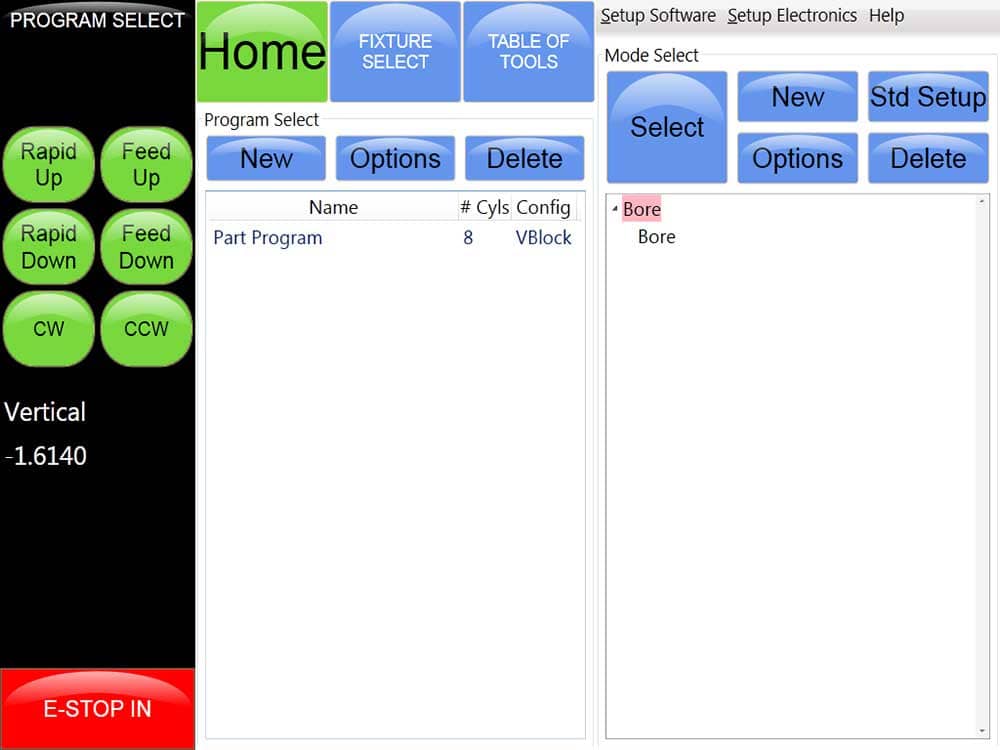

- CNC Touch Screen Control, Windows Operating System with Intel Processor

- Internet connection to the boring bar machine computer must be provided for training support and service.

- Automatic Vertical Cycles for Cylinder Boring, Resleeving and Counterboring

- Programming and Machine Operation thru extra bright touch screen.

- Electronic Handwheel for manual operation in .001″ (.01mm) or .005″ (.125mm) increments per Handwheel Detent

- Precision Digital Readout, .0001″ (.002mm) Resolution

- Spindle Travel by Precision Ball Screw & AC Servo Motor – Infinitely Variable

- Vertical Movement – Z Axis – Up and Down – 13″ (330mm)

- Spindle Rotation by AC Servo Motor – Infinitely Variable to 1200 RPM

- Machine Workhead Floats on Air Cushion for Precision Centering controlled from the Touch Screen – Total Travel – Left/Right Direction 40″ 1000mm

- Heavy Duty Spindle 2.68″ (68mm) Diameter with Inner Precision Angular Contact Bearings supported in Adjustable Outer Bearings

- Quick Change Cutterhead System

Give us a call, we have all the answers for you.

Rottler F9A specifications

| Control | Automatic CNC |

| Touch Screen | 114mm |

| Machine Height | 2032mm |

| Table - Size | 1270 x 530mm |

| Travel - Spindle Nose to Table | 670mm |

| Spindle - Rotation Speed | 100 to 1200 RPM |

| Spindle - Motor | 3.3 HP 2.5kW HP |

| Bore Capacity (with Optional Cutterheads) | 38 - 127mm |

| Feed per Revolution | Programmable Feed Rates .025 - .300mm |

| Spindle Travel (Vertical) | 330mm |

| Workhead Travel (Horizontal) | 1000mm |

| Dimensions - Machine | 1143D x 1956W x 2032mm H |

| Dimensions - Floor Space Requirements | 1170D x 1372Wmm |

| Dimensions - Shipping | 1854D x 2362W x 2362mm H |

| Machine Weight | 1678 kg |

| Electrical Requirements | 208-240V, 30A, 50/60Hz, 1Ph |

| Air Requirements | 28 l/min @ 6 bar |

| Paint Color Code | RAL9002 (Grey White) |

| Dimensions - Floor Space Requirements | 2565D x 3708Wmm |

| Dimensions - Shipping | 2286D x 3073W x 2794mm H |

| Machine Weight | 5546 kg |

| Electrical Requirements | 208-240V, 60A, 50/60Hz, 3Ph |

| Air Requirements | 6 l/min @ X bar |

| Paint Color Code | RAL9002 (Grey White) |

Control

The F9A utilizes a user-friendly CNC Touch Screen Control powered by a Windows Operating System with Intel Processor. It offers instant Internet Support for convenient troubleshooting. Additionally, the electronic handwheel enables Manual Operation with two modes. In coarse mode, each click adjusts the machine precisely by 0,01mm, while in fine mode, each click adjusts it by 0,002mm. The pulse handwheel allows for feed options of 0,002mm or 0,01mm per click, while the LED displays the accurate vertical position in 0,002mm increments.