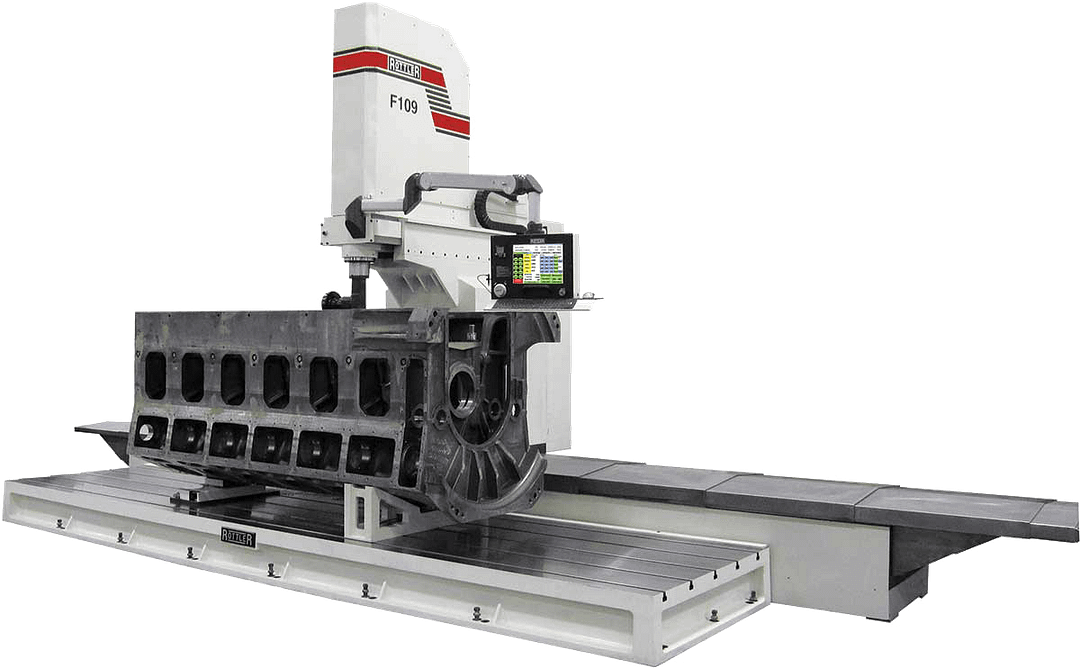

Discover the Rottler EM109H Traveling Column Boring, Surfacing & Line Boring Machine including HSK80A Spindle Taper

The Ultimate Solution for Precision Engine Machining

Are you searching for a reliable and high-performance machine for your engine machining needs in Europe? Look no further than the Rottler EM109H Traveling Column Boring, Surfacing & Line Boring Machine. Engineered to deliver exceptional results, this cutting-edge equipment is designed to meet the demands of the most advanced engine machining applications.

Unparalleled Precision and Efficiency

The Rottler EM109H stands out as a leader in precision engine machining, providing unmatched accuracy and efficiency. With its advanced features and innovative technology, this machine ensures that every machining process is carried out with the utmost precision, resulting in superior performance and quality.

Key Features and Benefits

The Rottler EM109H boasts a range of features that set it apart from the competition. Here are some of the key highlights:

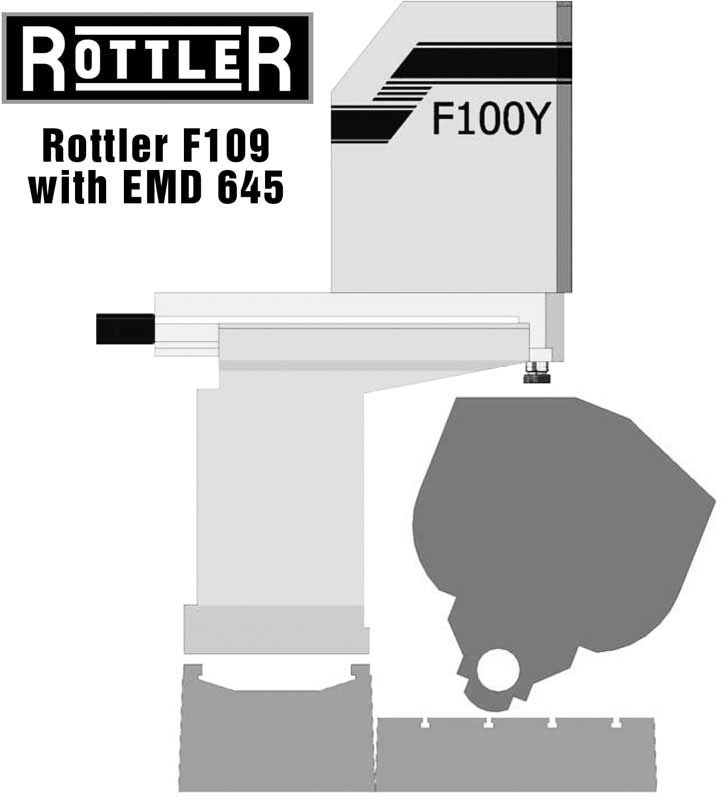

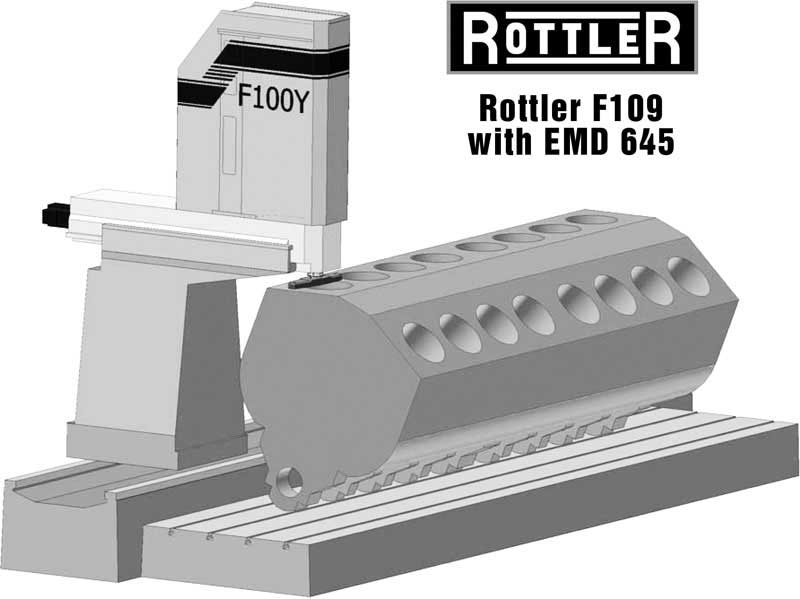

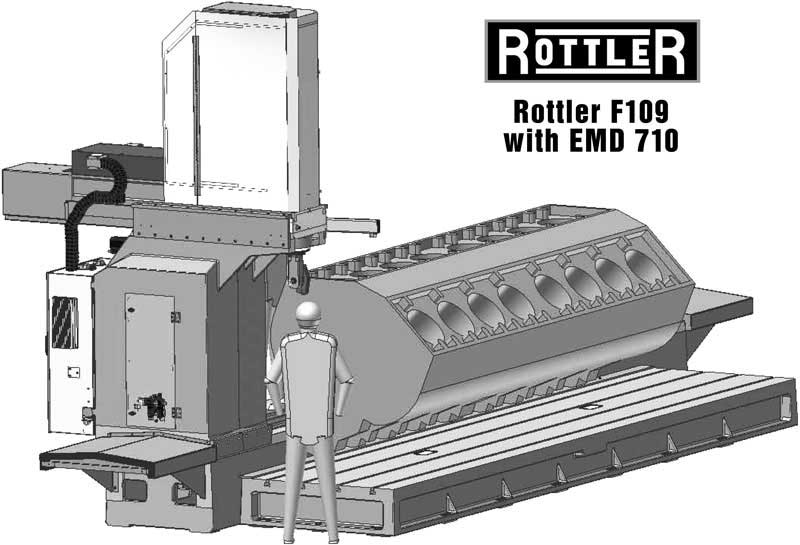

Traveling Column Design: The unique traveling column design enables versatile machining capabilities, allowing you to perform a variety of operations with ease.

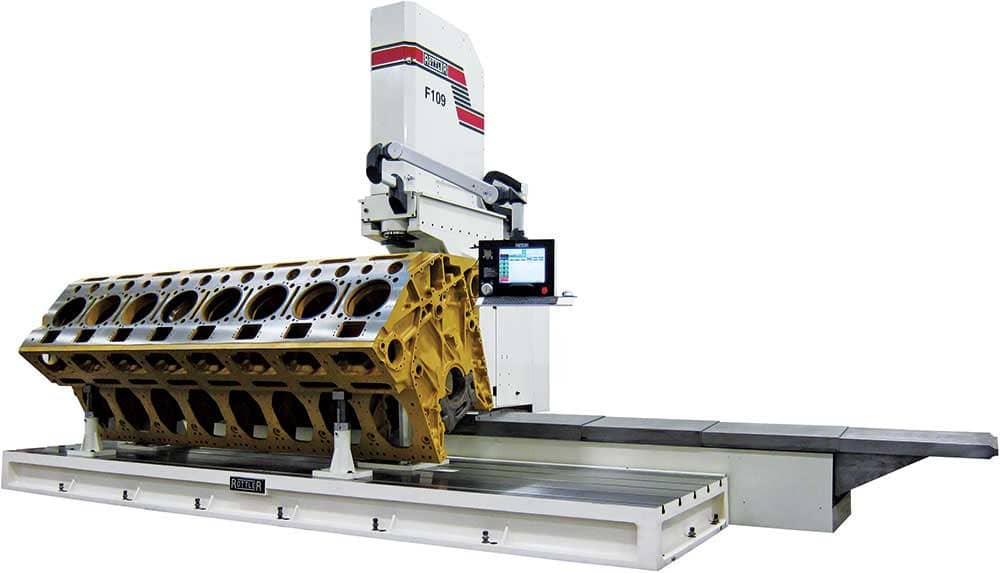

Line Boring Functionality: With its integrated line boring capabilities, the EM109H allows you to achieve precise alignment and sizing of bores, ensuring optimal performance and longevity of engine components.

Surfacing Excellence: The machine’s surfacing capabilities deliver exceptional flatness and finish, ensuring superior sealing and gasket performance.

CNC Precision: Equipped with state-of-the-art CNC technology, the EM109H guarantees accuracy and repeatability, reducing human error and increasing overall productivity.

European Expertise: Rottler Machines Europe is your trusted partner for all your engine machining needs. With years of experience and a dedicated team of professionals, we provide exceptional customer service and support throughout Europe.

Why Choose Rottler Machines Europe?

At Rottler Machines Europe, we understand the unique requirements of European engine machining professionals. By choosing our services, you benefit from:

Industry-leading Solutions: We offer cutting-edge machinery designed to meet the stringent demands of the European market, ensuring superior performance and productivity.

Extensive Product Range: In addition to the Rottler EM109H, we provide a comprehensive selection of engine machining equipment and accessories to cater to all your needs.

Expert Technical Support: Our team of experienced technicians is always ready to assist you with installation, training, and ongoing technical support to ensure optimal performance and maximum uptime.

Competitive Pricing: We offer competitive pricing options without compromising on quality, making our machines and services accessible to a wide range of customers.

Contact Us Today

If you’re ready to take your engine machining capabilities to the next level with the Rottler EM109H Traveling Column Boring, Surfacing & Line Boring Machine, contact Rottler Machines Europe today. Discover the power of precision and efficiency, backed by our industry expertise and commitment to customer satisfaction. Let us help you achieve unparalleled results for your engine machining needs in Europe.

We have more then 100 years of experience

We have more then 100 years of experience

Discover the Impressive Features of the Rottler EM109H Traveling Column Boring, Surfacing & Line Boring Machine

Precision Engineering for Optimal Performance

When it comes to precision engine machining, the Rottler EM109H Traveling Column Boring, Surfacing & Line Boring Machine is in a league of its own. Engineered with top-notch features, this machine ensures exceptional performance and delivers outstanding results for your machining needs.

Key Features for Unmatched Precision

The Rottler EM109H boasts a range of remarkable features that set it apart from the competition. Let’s explore these features and understand how they contribute to the machine’s precision and efficiency:

Large Diameter Hard Chromed Spindle: The EM109H incorporates a robust spindle with a large diameter, featuring high precision angular contact bearings and automatic lubrication. This ensures smooth and precise rotation, reducing friction and enhancing longevity.

Induction Hardened Machine Ways: The machine ways of the EM109H are induction hardened, coated with turcite low friction material, and supplied with air pressure. This combination significantly reduces friction, extending the machine’s service life and providing smooth operation.

Anti-Friction Ball Screws and AC Servo Motors: With anti-friction ball screws and AC servo motors, the EM109H delivers precise machine positioning and rapid feed rates. This allows for accurate and efficient machining, ensuring consistent results every time.

Air Power Drawbar: The air power drawbar feature of the EM109H enables quick and effortless changes of cutterheads, increasing productivity and reducing operator fatigue. In less than 15 seconds, the machine can transition from boring to surfacing operations.

Automated Workhead Tilting System: The EM109H is equipped with an automated workhead tilting system specifically designed for surfacing. This system provides “back clearance,” resulting in superior surface finish and ensuring excellent quality.

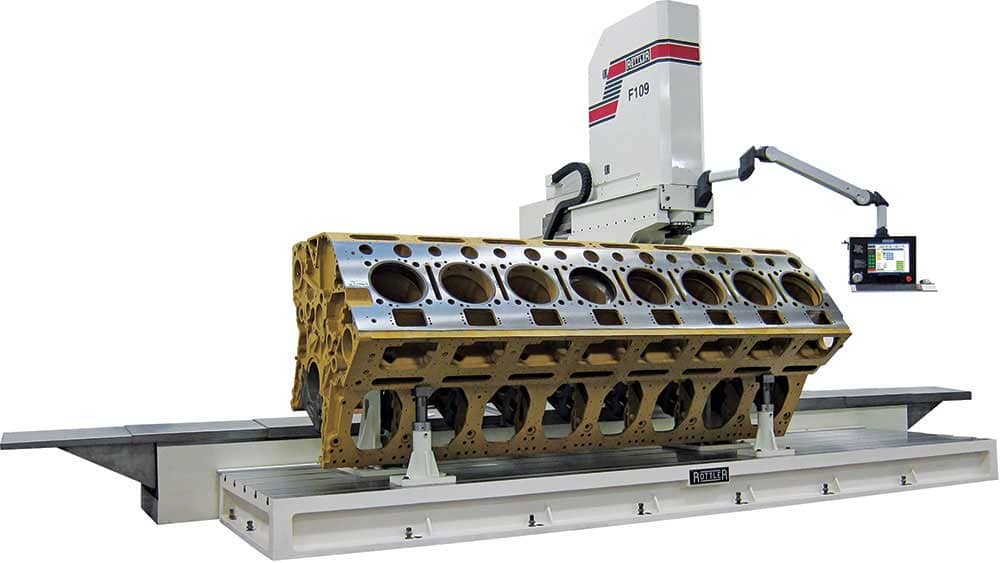

Increased Clearance: The Rottler EM109H offers enhanced clearance from the spindle centerline to the machine’s column. This feature allows for the setup and machining of large castings, expanding the machine’s capabilities and versatility.

Unleash Your Machining Potential with Rottler

Rottler Machines Europe is proud to offer the Rottler EM109H Traveling Column Boring, Surfacing & Line Boring Machine with its impressive array of features. Our commitment to providing top-quality machinery and exceptional customer service sets us apart in the industry.

With Rottler, you can expect:

Precision Engineering Expertise: We bring decades of experience in precision engineering to the table. Our machines are meticulously designed and manufactured to meet the demands of the most challenging machining applications.

Reliability and Longevity: Rottler machines are built to last. The EM109H’s durable construction and advanced features ensure long-term reliability and minimal downtime.

Efficiency and Productivity: By investing in the EM109H, you gain a machine that optimizes your productivity. The rapid feed rates, quick tool changes, and automated features streamline your operations, maximizing efficiency.

Comprehensive Support: Rottler Machines Europe provides comprehensive support, including installation assistance, training, and ongoing technical guidance. Our team of experts is dedicated to helping you achieve the best results with your Rottler machine.

Take Your Engine Machining to New Heights

Ready to experience the unmatched precision and efficiency of the Rottler EM109H Traveling Column Boring, Surfacing & Line Boring Machine? Contact Rottler Machines Europe today to learn more about this exceptional piece of equipment. Let us help you elevate your engine machining capabilities and achieve superior results with Rottler by your side.

Machine Operations

- Automatic Tool Changer

- Block Surfacing

- Blue Print Boring

- Boring & Sleeving

- Circular Interpolation

- Connecting Rod Boring

- Cylinder Boring

- Cylinder Head Resurfacing

- Lifter Boring

- Line Boring

- Multi Purpose CNC (Custom Parts)

- Thrust Cutting

Rottler EM109H Standard Equipment

Standard equipment that comes with the Rottler EM107H Traveling Column Boring Machine:

- CNC (Computer Numerical Control) Machine Using Windows Operating System and Industrial PC with Intel Processor.

- Programming and Control Thru A 19″ (483mm) Computerized Touch Screen.

- Precision Position Display in .0001″ (.002mm) Resolution

- Software Options Available for Programmable Automated Cycles Such as Boring, Surfacing, Lower Sleeve Offset Boring, Water Hole Repairs, Main & Cam Line Boring, General CNC Machine Work

- USB Flash Drive for File Transfer to and From Computer

- Internet connection to the machine computer must be provided for training support and service.

- Machine/Computer Can Operate In Either Inch Or Metric System

- High Torque Servo Spindle Motor – Continuous 1925 in.lbs – 220NM. Peak 5775 in.lbs – 652NM

- Spindle Rotation Speed – Infinitely Variable 0-1000RPM

- Hard Chromed Precision Spindle Diameter 6″ (150mm) with High Speed Angular Contact Bearings

- SPINDLE TAPER – HSK80A QUICK CHANGE allows Automatic Tool Changing System

- DIRECT DRIVE 3 Axis Movement by Precision Ball Screws & AC Servo Motors – Infinitely Variable

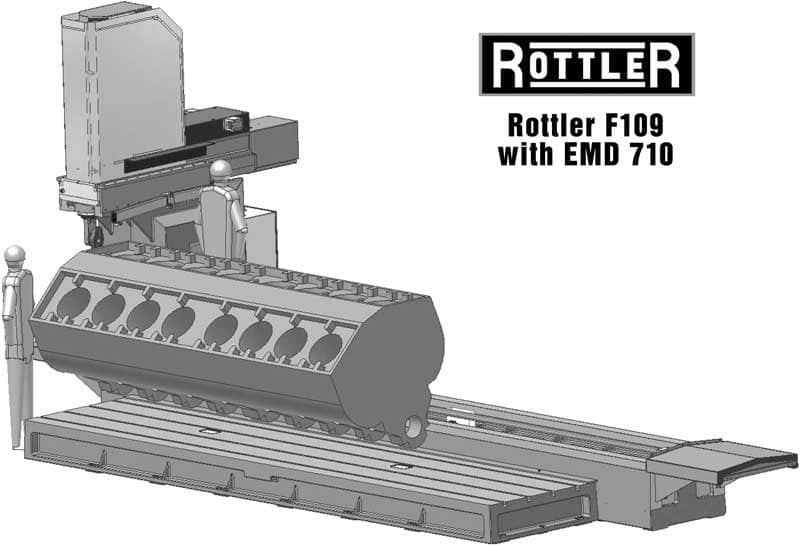

- Horizontal Movement (X Axis) – Left and Right Direction – 248″ (6300mm)

- Horizontal Movement (Y Axis) – In and Out Direction – 24″ (610mm)

- Vertical Movement (Z Axis) – Up and Down – 36″ (915mm)

- Vertical, Horizontal and Spindle Load Monitoring for Fast Overload Shut Down

- Electronic Hand Wheel for Manual Movement – Per Click: Coarse Mode .01″ (.25mm) Medium Mode .001″ (.01mm) Fine Mode .0001″ (.002mm)

- Infinitely Variable Feedrates Adjustable by Hand Wheel During Automatic Cycles

- Fast Rapid and Jog Speeds for Reduced Cycle Time

- Automatic Work Head Tilt System for Back Clearance During Surfacing

- Air Assisted Quick Change Cutterhead Draw Bar System

- Heat Treated Mehanite Cast Iron Machine Castings

- Air Pressurized Column for Less Friction and Accurate Positioning

- Turcite Coated Slideways for Low Friction and Extended Life

- Automatic Central Lubrication System Monitored by Computer

- Chip Guard vertically adjustable with 2 LED work lights

- Operation, Programming and Spare Parts Manual -Digital

- Paint Color Code: RAL9002 (Grey White)

Give us a call, we have all the answers for you.

Rottler EM109H specifications

| Control | Automatic |

| Touch Screen | 381mm |

| Table - Size | 1700 x 6100mm |

| Table - T Slots | 4 |

| Travel - Horizontal (X Axis) | 6300mm |

| Travel - In/Out (Y Axis) | 600mm |

| Travel - Vertical (Z Axis) | 915mm |

| Travel - Spindle Nose to Table | 1716mm |

| Travel - Spindle Center to Column | 1100mm |

| Spindle - Rotation Speed | 0 to 1000 RPM |

| Spindle - Motor | 12.75 Kw |

| Cylinder Bore Range (with Optional Cutterheads) | 19 - 500mm |

| Line Bore Range (with Optional Cutterheads) | 50 - 300mm |

| Surfacing Cutterhead Diameters | 250, 340, 460 & 575mm |

| Dimensions - Floor Space Requirements | 4216D x 9200Wmm |

| Machine Weight | 20412 kg |

| Electrical Requirements | 220V, 60A, 50/60Hz, 3Ph |

| Air Requirements | l/min @ 6 bar |

| Paint Color Code | RAL9002 (Grey White) |

Experience the Power of Automation with Rottler EM100 Machines

Pioneering Automation with Cutting-Edge Technology

Over 20 years ago, Rottler revolutionized the industry by introducing automation through electronics and computers. Today, we continue to push the boundaries of innovation by harnessing the latest computer technology, making automation easy to learn, versatile to operate, and future-ready for software upgrades.

Simplified Operator Interface with Touch Screen Control

At Rottler, we prioritize user-friendliness and efficiency. Our EM100 machines feature a Windows operating system and touch screen control, providing a simple operator interface. The touch screen control displays only the necessary buttons and information for each operation, effectively “hiding” complex computer functions in the background. This intuitive design allows operators to focus on the task at hand and quickly learn advanced machining functions within a few days.

Streamlined Automation for Common Jobs

The EM100 machines excel in automating everyday tasks such as boring, surfacing, and line boring. Once the machine is set up, operator attendance is only required during the initial setup phase. The machine takes charge and automatically performs bore operations along a complete cylinder bank or line boring along a main line, reducing the need for constant monitoring.

Precision and Flexibility in Surfacing

When surfacing a block, multiple passes are often necessary to achieve the desired results. With the EM100, you can program multiple passes, ensuring the machine moves down the exact amount for each pass. The final pass includes a finish cut, delivering the required surface finish with precision and consistency.

Efficiency through Automated Positioning

The EM100 simplifies positioning by automatically moving to exact positions based on measurements from the block or blueprint. This feature proves invaluable for jobs that require multiple boring operations, such as resleeving. Additionally, for special applications, the Optional Renishaw Wireless Probing enables the machine to automatically locate bore centers and measure diameters, further enhancing efficiency.

Automatic Lower Sleeve Repair Software

In cases where resleeving the lower seal area of wet liner blocks is necessary, the EM100’s Automatic Lower Sleeve Repair Software comes to the rescue. The machine is programmed to offset the boring tool to clear the upper diameter, move down, and then return on center to bore the lower area precisely aligned with the upper bore. Once the boring is complete, the machine automatically indexes the cutting tool, offsets the programmed amount, retracts, and continues to the next cylinder, all without operator intervention.

Unlock the Full Potential of Automation with Rottler

Rottler’s dedication to automation, advanced technology, and user-friendly interfaces sets us apart in the industry. With our EM100 machines, you can harness the power of automation to streamline your operations, increase productivity, and achieve exceptional results.

Discover the Rottler Difference Today

Are you ready to experience the benefits of automation in your machining processes? Contact us at Rottler to learn more about our EM100 machines and how they can revolutionize your operations. Our team is committed to providing top-notch support and guidance, ensuring that you unlock the full potential of automation with Rottler by your side.