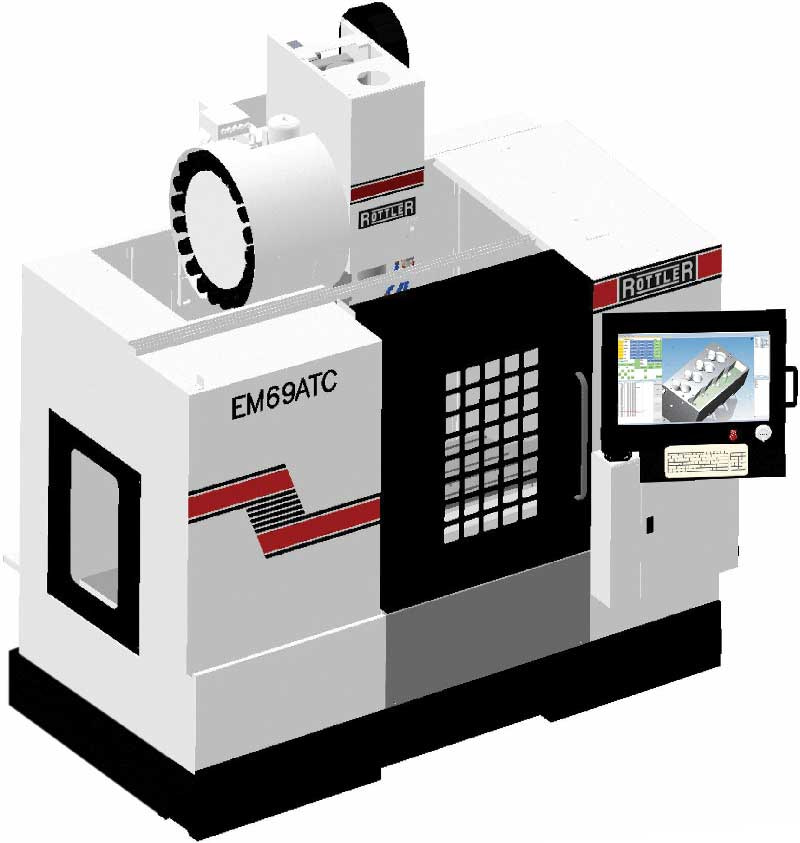

Rottler EM69ATC: Advanced Linear Rail Engine Machining Center

Experience Precision and Efficiency with the EM69ATC Machining Center

Are you in search of a cutting-edge engine machining solution that combines precision, efficiency, and advanced technology? Look no further than the Rottler EM69ATC, a state-of-the-art linear rail engine machining center designed to meet the demands of modern engine builders and enthusiasts.

At Rottler Manufacturing, we understand the importance of precision and accuracy when it comes to machining engine components. That’s why we’ve developed the EM69ATC, a machining center that sets new industry standards. With its advanced features and cutting-edge capabilities, the EM69ATC delivers outstanding results, whether you’re working on a single engine or mass-producing engine blocks.

Unparalleled Performance and Technology

The Rottler EM69ATC combines the power of computer numerical control (CNC) technology with the stability and precision of linear rail design. This innovative combination ensures superior machining accuracy and repeatability, allowing you to achieve tight tolerances and produce high-quality engine components consistently.

Equipped with an automatic tool changer (ATC), the EM69ATC streamlines the machining process, eliminating manual tool changes and reducing downtime. This automated system enhances productivity and efficiency, enabling you to optimize your workflow and complete projects faster.

Applications and Versatility

The EM69ATC is a versatile machining center capable of handling a wide range of engine components. From cylinder heads and engine blocks to intricate intake manifolds and connecting rods, the EM69ATC provides the flexibility and precision required for various machining applications.

Whether you’re a performance engine builder, a racing team, or an automotive manufacturer, the EM69ATC offers the capabilities and performance you need to achieve outstanding results. Its advanced features and user-friendly interface make it suitable for both experienced machinists and those new to CNC machining.

Why Choose Rottler EM69ATC?

- Advanced Linear Rail Design: The EM69ATC’s linear rail system ensures exceptional stability, minimizing vibrations and maximizing machining accuracy.

- Automatic Tool Changer (ATC): With its built-in ATC, the EM69ATC enables seamless tool changes, reducing manual intervention and optimizing production efficiency.

- CNC Precision and Control: Benefit from the precision and control of CNC technology, allowing you to achieve the tight tolerances required for high-performance engine components.

- Versatility and Adaptability: The EM69ATC accommodates a wide range of engine components, making it suitable for various machining applications.

- Trusted Manufacturer: Rottler Manufacturing is a reputable company with a long-standing history of delivering high-quality machining solutions to the automotive industry.

Experience the power of precision and efficiency with the Rottler EM69ATC linear rail engine machining center. Unlock new possibilities for your engine building projects and stay ahead of the competition with our cutting-edge technology and unmatched performance.

We have more then 100 years of experience

We have more then 100 years of experience

Features

Featues of the Rottler EM69ATC Traveling Column Boring, Surfacing & Line Boring Machine:

- Instant Internet Support – Rottler offers cutting edge internet support direct from your machine to the factory. Skype is installed for internet support. This feature gives you instant, direct contact with Rottler right on the machine without even making a phone call.

- Automatic Tool Changer – 24 Space Automatic Tool Changer for CAT40 Taper tools. The tool changer can handle up to a 10″ (250mm) diameter tool weighing 15.5lbs (7kgs).

- Windows Operating System – Rottler uses Windows and Touch Screen Technology/ through a 32″ (813mm) panel. The Windows software has many advantages such as a common user interface that the whole world is familiar with.

- Touch Screen Control – Two different operating systems are available. (1) The Rottler system for simple, fast and easy programming of common jobs such as boring, surfacing and line boring. Anyone can learn in a few hours. (2) The other is the Optional 4C CAD/CAM software for advanced CNC programming for endless opportunities such as making parts, engraving names and much more.

- Brushless Servo Motors with BISS Encoders – The EM69ATC has the latest technology servo motors with BISS encoders offering 100 times finer resolution compared to previous models. These new Servo motors give maximum torque and performance throughout the RPM range for improved accuracy and increased productivity. BISS encoders eliminate any limit switches and do not require homing at star up saving time and increasing reliability.

- Electronic Hand Wheel – Offers operator infinite control of machine movement in all axes for quick and easy setup. Also controls variable feed rate during automatic cycles.

- Spindle – Super hard finish resists wear for years of operation. 0-10,000 RPM Spindle Rotation with quick change CAT40 Taper.

- Massive Frame – Massive Frame boasts full enclosure with Sight Panels in front and on sides of enclosure to view work area.

- Direct Drive Ball Screws – Direct drive precision ball screws for faster rapid feed rates and accurate positioning eliminating backlash problems relating to belt drive systems.

- Linear Roller Slideways – All Axes of the EM machines are supported on low friction Linear Roller Bearing Slideways allowing fast acceleration and precise positioning for more production and precision parts.

- Large T-Slot Table – Allows operator to clamp or fixture any job quickly and easily.

- Coolant Tank – Complete coolant system for tool lubrication during machining. 30 gallon capacity.

- Automatic Lubrication – For years of trouble free life and reduced wear.

- Chip Auger – Automatically removes chips from enclosure and deposits chips in wheeled disposal cart.

Machine Operations

- Automatic Tool Changer

- Block Surfacing

- Blue Print Boring

- Boring & Sleeving

- Circular Interpolation

- Cylinder Boring

- Cylinder Head Resurfacing

- Lifter Boring

- Line Boring

- Multi Purpose CNC (Custom Parts)

- Thrust Cutting

Rottler EM69ATC Standard Equipment

Standard equipment that comes with the Rottler EM69ATC Multi Purpose Vertical CNC Machining Center:

- CNC (Computer Numerical Control) Machine using Windows Operating System and Industrial PC with Intel Processor. Precision Programming and Control through a 32″ (313mm) Computerized Touch Screen.

- Software options available for Programmable & Automated Cycles such as Boring, Surfacing, Lower Sleeve Offset Boring, Water Hole Repairs, Main & Cam Line Boring, General CNC Machine Work and more.

- Internet connection to the machine computer must be provided for training support and service.

- Programming and Machine Operation Thru 32” (813mm) Extra BrightTouch Screen

- Electronic hand wheel for manual movement – per click: Coarse Mode .01” (.25mm) Medium Mode .001” (.01mm) Fine Mode .0001” (.002mm)

- Precision Digital Readout, .0001” (.002mm) Resolution in 3 Axis

- Machine Prepared for 4th axis fixture upgrade

- 3 Axis Movement by direct drive Precision Ball Screws & AC Servo Motors – Infinitely Variable Horizontal Movement – Left and Right Direction – 40.5” (1028mm)

- Extra Clearance Between Spindle Nose and Machine Table – 40″ (1016mm)

- High Speed, Rigid Spindle for Chatter Free Cutting

- Spindle Rotation by AC Servo Motor – Infinitely Variable 0-8,000RPM

- Automatic Central Lubrication System

- 24 Space Tool Changer for CAT 40 Taper

- Full Enclosure with Sight Panels of Work Area

- Complete Coolant System for Tool Lubrication During Machining

- Operation and Spare Parts Manual

- Chip auger for chip removal

Give us a call, we have all the answers for you.

Rottler EM69ATC specifications

| Control | Rottler CNC |

| Spindle - Motor Torque | 95NM |

| Slideway Type (X/Y/Z) | Linear Roller Bearing Slideways |

| Axis Feed Method (X/Y/Z) | Direct Coupled Servo Driven Ball Screw |

| Table - Size | 500 x 1500mm |

| Table - T Slots | 5 |

| Travel - Horizontal (X Axis) | 1028mm |

| Travel - In/Out (Y Axis) | 520mm |

| Travel - Vertical (Z Axis) | 775mm |

| Travel - Spindle Nose to Table | 1016mm |

| Spindle - Taper | CAT40 |

| Spindle - Rotation Speed | 0 to 8000 RPM |

| Coolant Capacity | 113 Liters |

| Weight Capacity | 700kgs |

| Tool Changer - Number of Tools | 24 |

| Tool Changer - Maximum Weight of Tool | 7kgs |

| Tool Changer - Maximum Length of Tool | 300mm |

| Dimensions - Machine | 2565D x 3225W x 2972mm H |

| Dimensions - Floor Space Requirements | 2565D x 3708Wmm |

| Dimensions - Shipping | 2286D x 3073W x 2794mm H |

| Machine Weight | 5546 kg |

| Electrical Requirements | 208-240V, 60A, 50/60Hz, 3Ph |

| Air Requirements | 6 l/min @ X bar |

| Paint Color Code | RAL9002 (Grey White) |

Control

Advanced 4C Software: Revolutionizing CNC Machining

Discover the Power of Rottler’s EM Series 4C Software

Are you in search of cutting-edge software that combines Computer Numeric Control (CNC), Computer-Aided Design (CAD), and Computer-Aided Manufacturing (CAM) capabilities? Look no further than Rottler’s advanced 4C Software, featured in our newest EM Series equipment. With its state-of-the-art Computer Measuring Machine (CMM), the 4C technology revolutionizes the machining industry.

Efficiency and Ease of Use

Rottler’s 4C Software allows users to digitize, edit designs, and begin cutting in record time. What sets it apart is its user-friendly interface, requiring less machining/programming expertise compared to many other systems. With this brand-new CNC machine CAD/CAM software, 3D CAD Solid Models can be imported or created directly at the machine. The built-in CAM functions empower users to semi-automatically and interactively create complex 3D tool paths from the CAD geometry.

Expanded Touch Screen and Information Display

One of the standout features of the EM Series equipped with 4C Software is its large 32″ touch screen. By maximizing the screen size, Rottler’s CAM software allows operators to access an unprecedented amount of information for their use. The user has complete control over the displayed information, enabling incremental and interactive functionality.

Key Features and Functionality

Dimensions Input through Touch Screen: Easily input essential parameters such as Bore Centers, Exact Depth, Speed, Feed, and more, directly via the touch screen interface. Automatic Cycle for Complete Bores: Complete bank of bores in an automatic cycle, reducing manual intervention and increasing productivity.

Lower Bore Relief and Off-Center Boring: Achieve precise Honing Clearance with lower bore relief and off-center boring capabilities.

Surfacing Multiple Pass: Programmable roughing and finishing functions enable the removal of any amount of material in a single automatic cycle. Set the desired deck height of the block, and the machine will cut to that height, eliminating guesswork.

Lifter Bore Machining: Accurately bore housings and bushings to their exact final size.

Automatic Line Bore Cycle: Complete all main bearing housings with utmost precision, ensuring accuracy within .0002″.

Face Main Line Thrust Bearing Faces: Achieve square alignment to the crankshaft centerline for enhanced performance.

Stroker Crank Connecting Rod and Bolt Clearance: Machine a radius to accommodate stroker crank connecting rods and ensure clearance for bolts.

Rottler PATH CNC Program: Seamlessly integrate with G code programming and enable file transfer with CAD/CAM programs for enhanced flexibility and compatibility.

Experience the power and versatility of Rottler’s Advanced 4C Software, setting new standards in CNC machining efficiency and ease of use. Unlock new possibilities for your machining projects and stay ahead of the competition with our cutting-edge technology and unmatched performance.