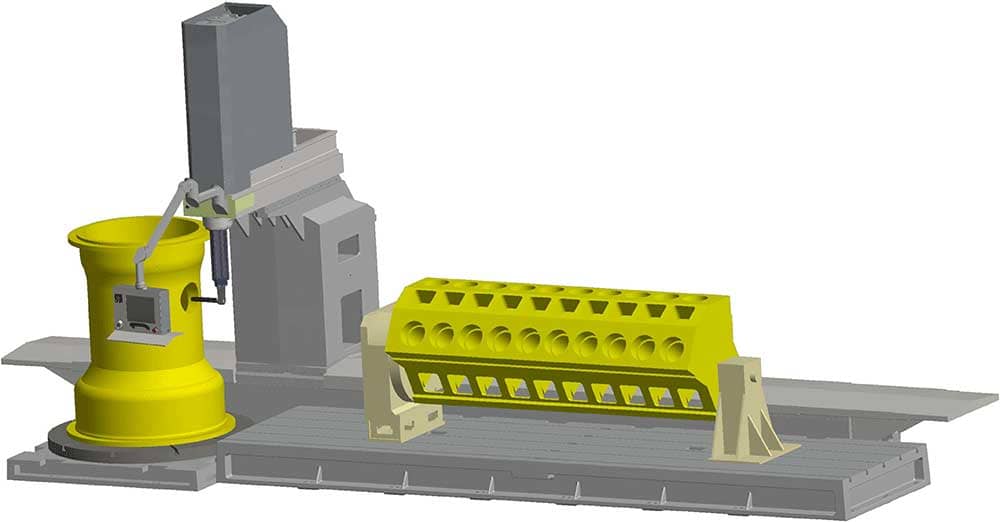

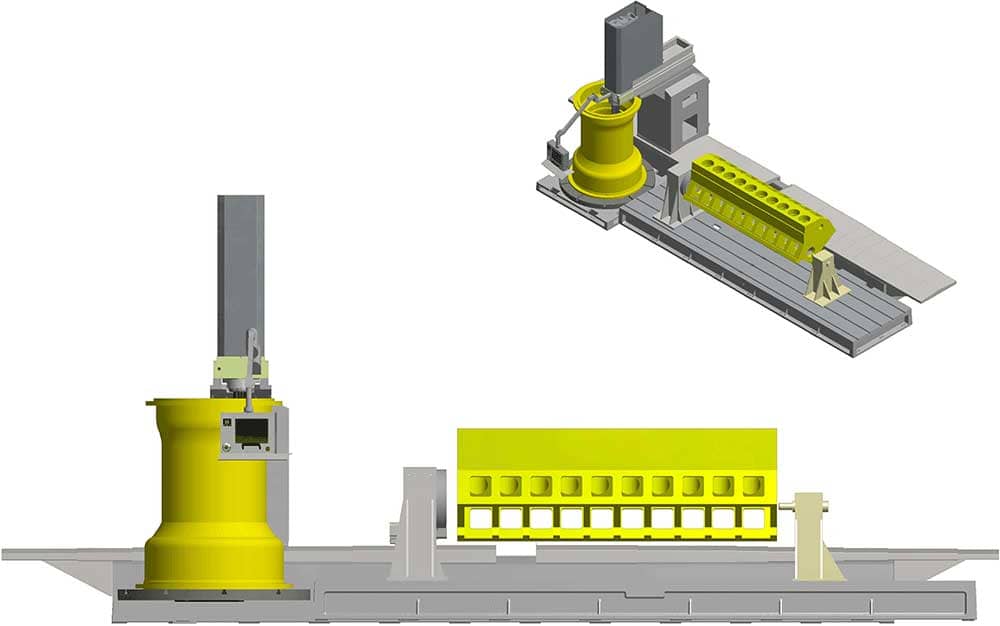

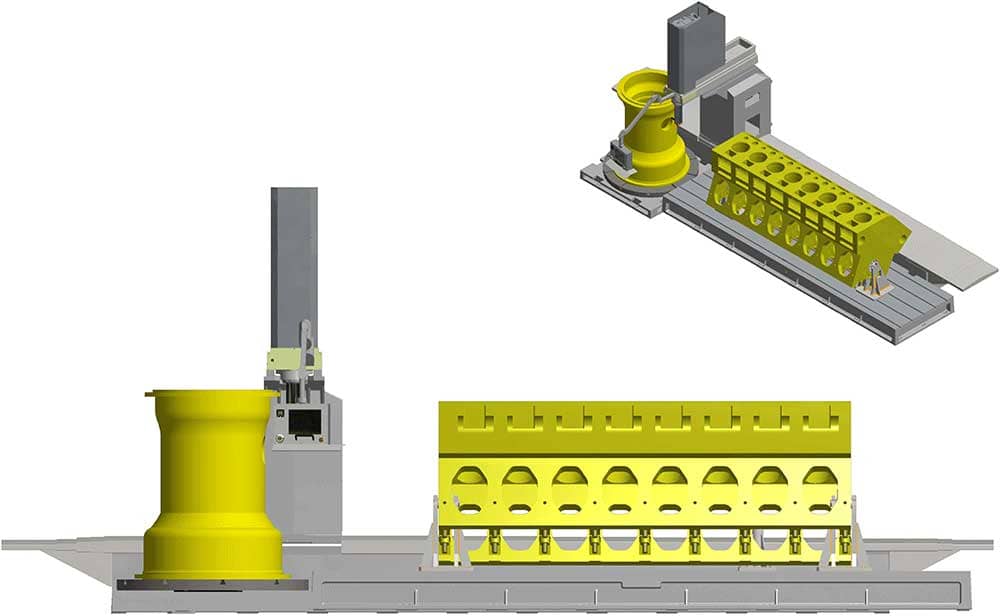

Rottler EM104H Traveling Column Boring, Surfacing & Line Boring Machine

Are you in search of a reliable and efficient machine for your engine machining needs? Look no further than the Rottler EM104H Traveling Column Boring, Surfacing & Line Boring Machine. With its advanced capabilities and precision engineering, the EM104H is designed to meet the demands of heavy-duty engine rebuilding and repair.

Precision Boring and Surfacing

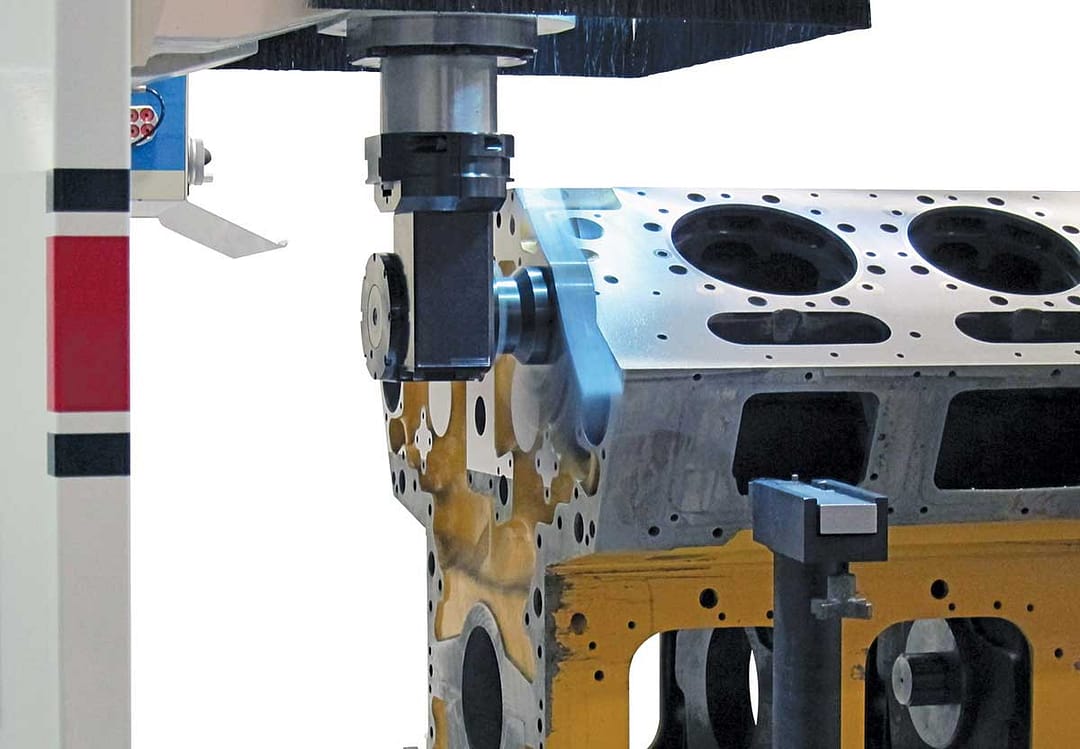

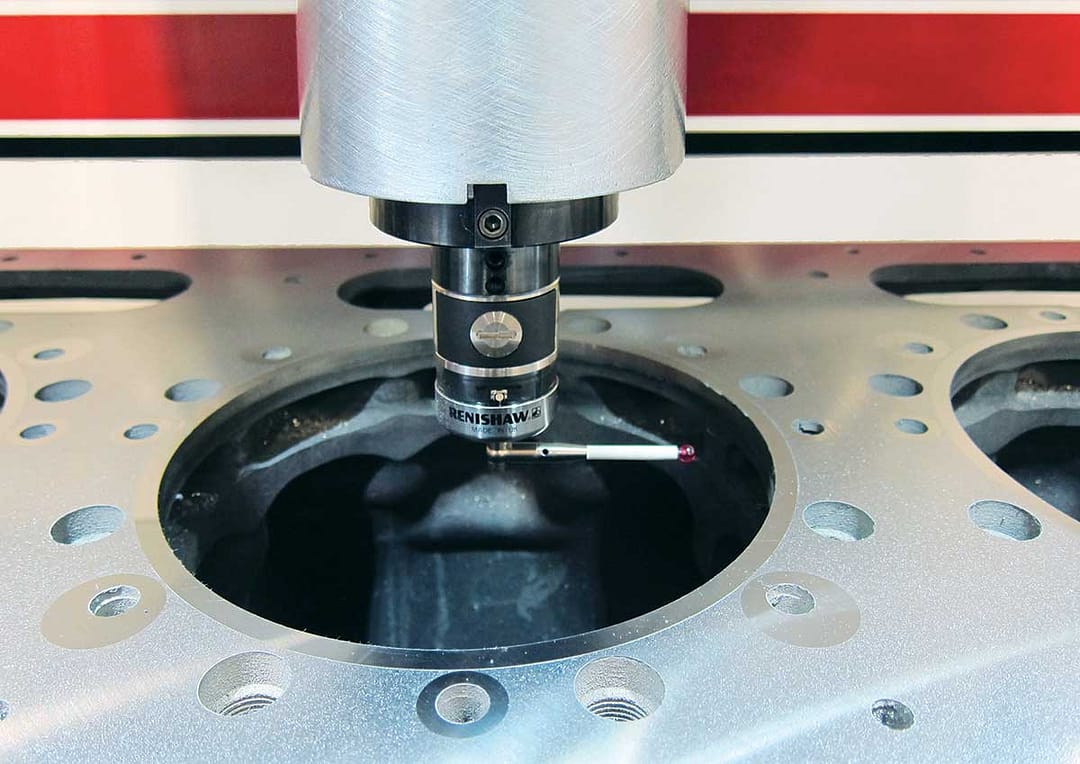

The Rottler EM104H is equipped with state-of-the-art CNC technology, ensuring accuracy and consistency in every machining operation. Whether you need to bore engine blocks, surface cylinder heads, or perform line boring, this machine offers exceptional precision to meet the highest industry standards.

With its traveling column design, the EM104H provides flexibility and ease of use. It allows for efficient setup and quick adjustments, saving you valuable time during your machining projects. The sturdy construction ensures stability and vibration-free operations, resulting in superior surface finishes.

Efficiency and Versatility

Engine rebuilders and machinists will appreciate the versatility of the Rottler EM104H. This machine is capable of handling a wide range of engine sizes and configurations. Whether you work on small engines or large diesel powerhouses, the EM104H has the capacity to accommodate your needs.

From precision boring of cylinder bores to accurate line boring of engine blocks, this machine offers comprehensive solutions for various engine repair tasks. Its advanced control system allows for easy programming and customization, making it an ideal choice for both experienced operators and those new to CNC machinery.

Reliability and Durability

When it comes to investing in machinery, durability is crucial. The Rottler EM104H is built to withstand the rigors of heavy usage in demanding automotive and industrial environments. Its robust construction and high-quality components ensure long-lasting performance and minimal downtime.

Engine rebuilders can rely on the EM104H to deliver consistent results, project after project. The machine’s cutting-edge features, combined with Rottler’s renowned expertise in engine machining, make it a trusted choice for professionals in the industry.

Conclusion

The Rottler EM104H Traveling Column Boring, Surfacing & Line Boring Machine is a powerful and reliable solution for your engine machining needs. With its precision, efficiency, and versatility, it enables you to achieve superior results in engine block repair, cylinder head resurfacing, and line boring operations.

Investing in the Rottler EM104H means investing in the future of your engine rebuilding business. Experience the advantages of advanced CNC technology, paired with durability and ease of use, all in one exceptional machine.

Contact us today to learn more about the Rottler EM104H and how it can elevate your engine machining capabilities.

We have more then 100 years of experience

We have more then 100 years of experience

Features

Featues of the Rottler EM104H Traveling Column Boring, Surfacing & Line Boring Machine:

- Productivity – Up to 75% time savings over traditional machines

- Control – Touch Screen Controls located on one panel for ease of operation

- Automation – Automatically machines precise dimensions

- Flexibility – Block boring and surfacing, head surfacing, line boring and general CNC machining.

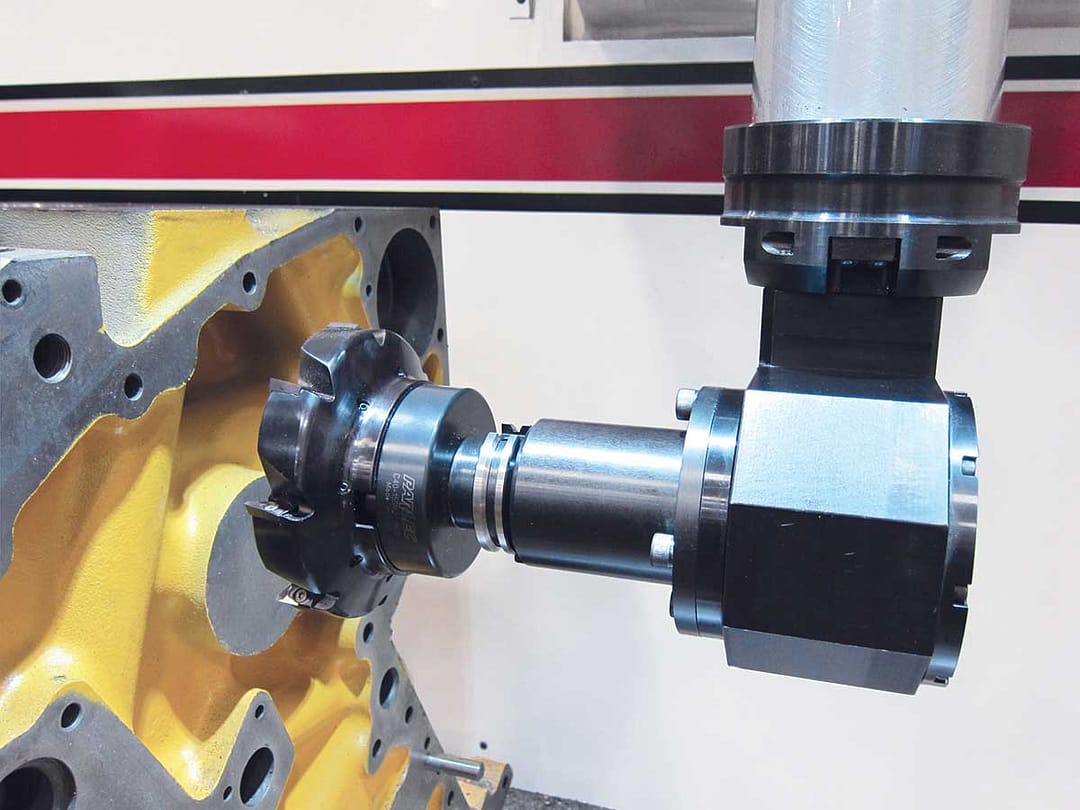

- Versatility – Change cutterheads from surfacing to boring and back in 15 seconds.

- Heavy Duty – Rottler rugged machine tool quality for accurate and long life. Heat treated mehanite cast iron castings.

- Large Diameter Spindle – All F100A machines incorporate the use of a large diameter hard chromed

spindle, utilizing high precision angular contact bearings and automatic lubrication. - Machine ways are induction hardened and coated with turcite low friction material and supplied with air pressure to reduce friction and give long service life. X-axis utilizes linear roller guideways for smooth and precise movement.

- Anti-friction Ball Screws and AC Servo motors provide precise machine positioning and rapid feed rates.

- Air power draw bar allows cutterheads to be changed in second, increasing productivity and reducing operator fatigue. The machine can be changed from boring to surfacing in less than 15 seconds.

- Automated workhead tilting system for surfacing provides “back clearance” for superior surface finish.

- Increased clearance from spindle to centerline to the machine’s column allow large castings to be set up and machined.

Machine Operations

- Automatic Tool Changer

- Block Surfacing

- Blue Print Boring

- Boring & Sleeving

- Circular Interpolation

- Connecting Rod Boring

- Cylinder Boring

- Cylinder Head Resurfacing

- Lifter Boring

- Line Boring

- Multi Purpose CNC (Custom Parts)

- Thrust Cutting

Rottler EM104H Standard Equipment

Standard equipment that comes with the Rottler EM103H Traveling Column Boring Machine:

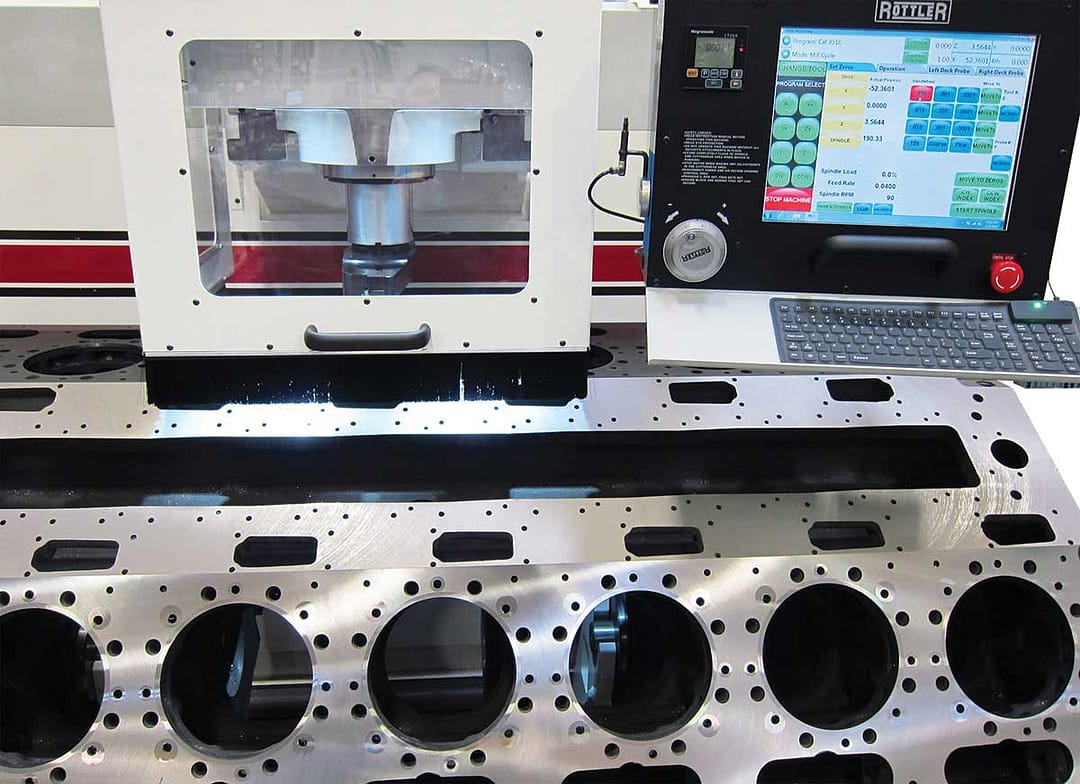

- CNC (Computer Numerical Control) Machine using Windows Operating System and Industrial PC with Intel Processor. Precision Programming and Control thru a 19″ (483mm) Computerized Touch Screen.

- Software options available for Programmable & Automated Cycles such as Boring, Surfacing, Lower Sleeve Offset Boring, Water Hole Repairs, Main & Cam Line Boring, General CNC Machine Work

- Spindle Rotation by AC Servo Motor – Infinitely Variable 0-5000RPM – 10HP (7.5kW)

- USB flash drive for file transfer to and from computer

- Machine/Computer can operate in either inch or metric system

- 3 Axis movement by Precision Ball Screws & AC Servo Motors – Infinitely Variable

- Horizontal Movement (X Axis) – Left and Right Direction – 108″ (2750mm)

- Horizontal Movement (Y Axis) – In And Out Direction – 16″ (406mm)

- Vertical Movement (Z Axis) – Up and Down – 29″ (736mm)

- Vertical, Horizontal and Spindle Load Monitoring for Fast Overload Shut Down

- Precision Position Display in .0001″ (.002mm) Resolution.

- Electronic Handwheel for manual movement – per click: Coarse Mode .01″(.25mm) Medium Mode .001″(.01mm) Fine Mode .0001″(.002mm)

- Infinitely Variable Feedrates adjustable by handwheel during automatic cycles

- High Performance Spindle Rotation AC Brushless Servo Motor and Drive System

- Hard Chromed Precision Spindle with High Speed Angular Contact Bearings

- Fast Rapid and Jog Speeds for Reduced Cycle Time

- Automatic Workhead Tilt System for Back Clearance during Surfacing

- Air Assisted Quick Change Cutterhead Draw Bar System

- One Piece Heat Treated Mehanite Cast Iron Machine Castings

- Air Pressurized Column for Less Friction and Accurate Positioning

- Turcite Coated Slideways for Low Friction and Extended Life

- Linear Roller Slideways in the X-axis for smooth and precise movement even under heavy load.

- LED Work Light (mounted)

- Automatic Central Lubrication System monitored by controller

- Chip Guard with Adjustable Pivot Arm

- Operation, Programming and Spare Parts Manual – Digital

Give us a call, we have all the answers for you.

Rottler EM103H specifications

| Control | CNC Touch Screen |

| Touch Screen | 381mm |

| Machine Height | 3480mm |

| Table - Size | 850 x 2820mm |

| Table - T Slots | 3 |

| Travel - Horizontal (X Axis) | 2750mm |

| Travel - In/Out (Y Axis) | 406mm |

| Travel - Vertical (Z Axis) | 736mm |

| Travel - Spindle Nose to Table | 1273mm |

| Travel - Spindle Center to Column | 648mm |

| Spindle - Rotation Speed | 0 to 1000 RPM |

| Spindle - Motor | 12.75 Kw |

| Cylinder Bore Range (with Optional Cutterheads) | 19 - 508mm |

| Line Bore Range (with Optional Cutterheads) | 48.5 - 216mm |

| Surfacing Cutterhead Diameters | 250, 360, 460 & 570mm |

| Dimensions - Machine | 2134D x 3962W x 3480mm H |

| Dimensions - Floor Space Requirements | 2438D x 5232Wmm |

| Dimensions - Shipping | 2184D x 3962W x 2286mm H |

| Machine Weight | 7711 kg |

| Electrical Requirements | 208-240V, 60A, 50Hz, 60Ph |

| Air Requirements | 28 l/min @ 6 bar |

| Paint Color Code | RAL9002 (Grey White) |

Control

Rottler has revolutionized CNC programming and machining with our latest development, an intuitive conversational programming system that is both easy to learn and operate. By leveraging our in-house CNC expertise and collaborating with software and programming experts, we have created a user-friendly system that simplifies the programming process.

Our conversational programming system replaces the traditional, complex G&M code programming with easy-to-understand icons and menus, resembling the familiar Windows style. This graphical interface makes it easier for operators to comprehend and navigate through the program. Say goodbye to the days of abstract coding!

With our system, you can take advantage of Windows-based functionalities that everyone is familiar with. File saving and copying to external laptops and desktop computers become a breeze. Moreover, thanks to the use of Windows technology, program sharing is made simple. Programs can be easily emailed worldwide via the Internet or transferred using USB flash memory drives.

Introducing Rottler PATH CAD/CAM (Computer-Aided Design and Manufacturing) Software, a powerful tool that enhances your programming experience. As you develop a program on the machine, laptop, or desktop, the software works silently in the background, calculating intricate tool paths and optimizing the machining process.

The software excels at converting drawings into complex CNC programs with minimal operator involvement. It automates many of the technical aspects, allowing you to focus on the creative and problem-solving aspects of your work. With Rottler PATH CAD/CAM Software, you can unleash your design ideas and let the machine do the heavy lifting.

Our user-friendly approach, combined with the power of Rottler PATH CAD/CAM Software, empowers operators of all technical levels to excel in CNC programming and machining. Whether you’re a seasoned professional or someone with limited technical knowledge, our system makes CNC programming more accessible and efficient than ever before.

Experience the future of CNC programming with Rottler’s conversational programming system and PATH CAD/CAM Software. Boost your productivity, unleash your creativity, and simplify your machining process with our innovative solutions. Contact us today to learn more and take your CNC programming to new heights.