Discover the Rottler EM69HP: The Ultimate High-Performance Engine Machining Center

Welcome to Rottler Manufacturing, where precision meets innovation. Are you in search of an advanced engine machining center that delivers exceptional results? Look no further than the Rottler EM69HP. As a leading player in the industry, we take pride in introducing this cutting-edge, linear rail-based machining center designed to meet the demands of even the most complex engine block machining projects.

Unleashing the Power of the Rottler EM69HP

Our flagship product, the Rottler EM69HP, is a true game-changer. Built with state-of-the-art technology, this CNC engine machining center is engineered to surpass your expectations. It combines speed, precision, and versatility, making it the go-to solution for engine builders, performance shops, and manufacturers alike.

With a focus on optimizing your machining processes, the Rottler EM69HP boasts an array of advanced features that set it apart from the competition. Its linear rail design ensures exceptional rigidity, minimizing vibration and maximizing accuracy during high-speed machining operations. This means you can achieve superior surface finishes, tighter tolerances, and improved overall part quality.

Unparalleled Precision and Performance

The Rottler EM69HP leaves no room for compromise when it comes to precision. Its robust spindle, coupled with advanced motion control technology, guarantees outstanding machining accuracy. This results in perfect alignment, excellent concentricity, and minimized runout, providing you with engine components that meet the highest industry standards.

Designed to handle a wide range of engine block sizes and configurations, the EM69HP offers incredible flexibility. Its intuitive CNC interface allows for effortless customization, enabling you to adapt to various machining requirements quickly. Whether you’re working on cylinder heads, engine blocks, or other complex components, the Rottler EM69HP is up to the task.

Invest in Success with Rottler EM69HP

When it comes to engine machining, time is of the essence. The Rottler EM69HP understands the need for efficiency and productivity. Its advanced tooling system, combined with rapid tool change capabilities, minimizes downtime, ensuring uninterrupted workflow. This means you can meet tight deadlines, improve turnaround times, and ultimately increase profitability.

At Rottler Manufacturing, we stand behind the performance and reliability of our products. Each Rottler EM69HP undergoes rigorous testing and quality checks to guarantee exceptional durability and longevity. With our machine in your workshop, you’ll experience minimal maintenance requirements, allowing you to focus on what truly matters – delivering top-notch results to your customers.

Find Your Perfect Rottler EM69HP Today

If you’re ready to take your engine machining capabilities to the next level, the Rottler EM69HP is the ideal choice. Experience the future of engine block machining with Rottler Manufacturing and the EM69HP. Contact us today to schedule a demonstration or request a quote.

The Cutting-Edge EM69HP: Unleashing the Power of Rottler’s Advanced Optional 4C Software

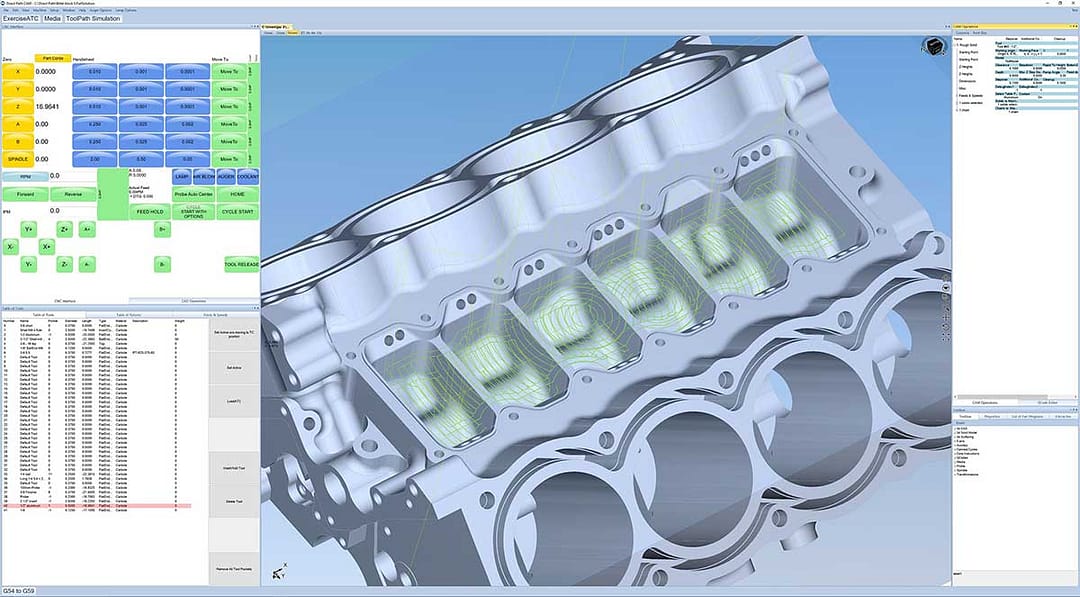

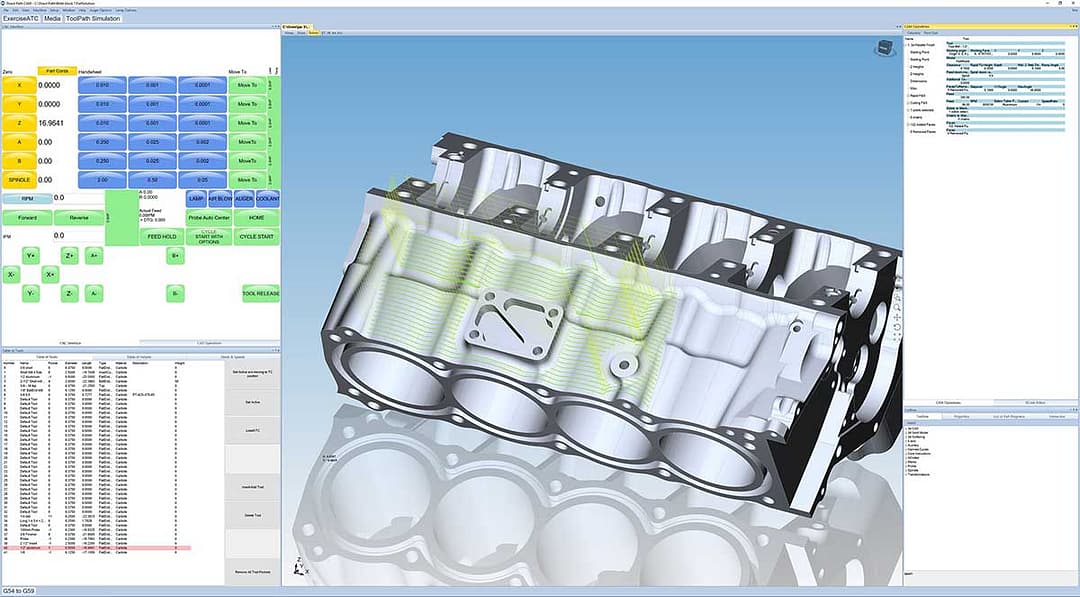

Experience the future of engine machining with the Rottler EM69HP, equipped with our revolutionary Advanced Optional 4C Software. This state-of-the-art control system, developed by Direct Motion, takes your machining capabilities to new heights, offering unrivaled interactivity, responsiveness, and precision.

Advanced Optional 4C Software: Empowering Engine Machining

The heart of the EM69HP lies in its PC-based single processor control system, powered by our Advanced Optional 4C Software. This highly advanced software is designed to enhance your machining experience by providing a seamless and intuitive interface that puts you in complete control.

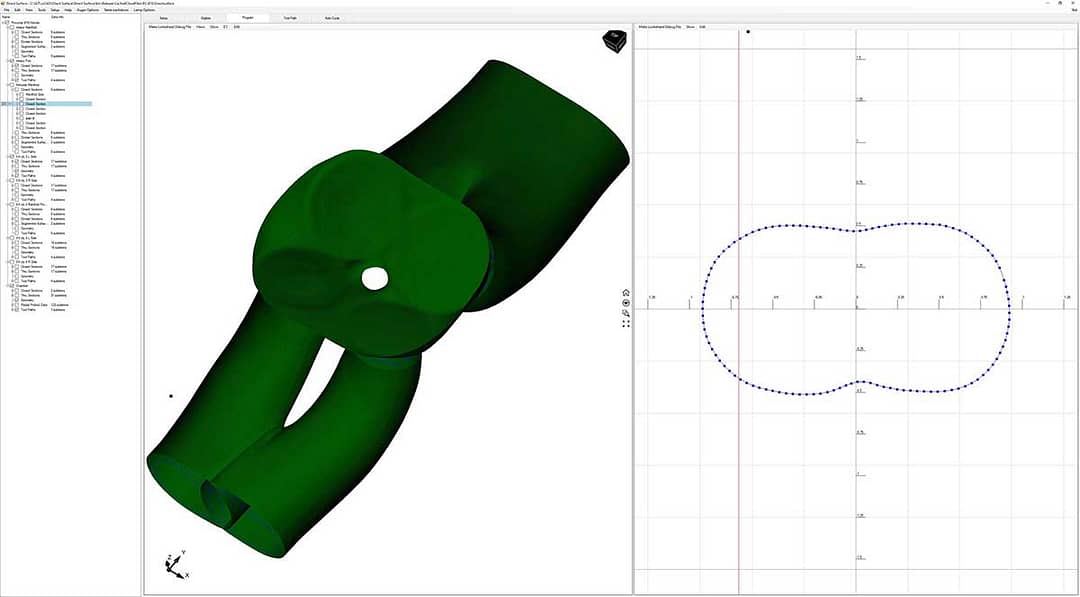

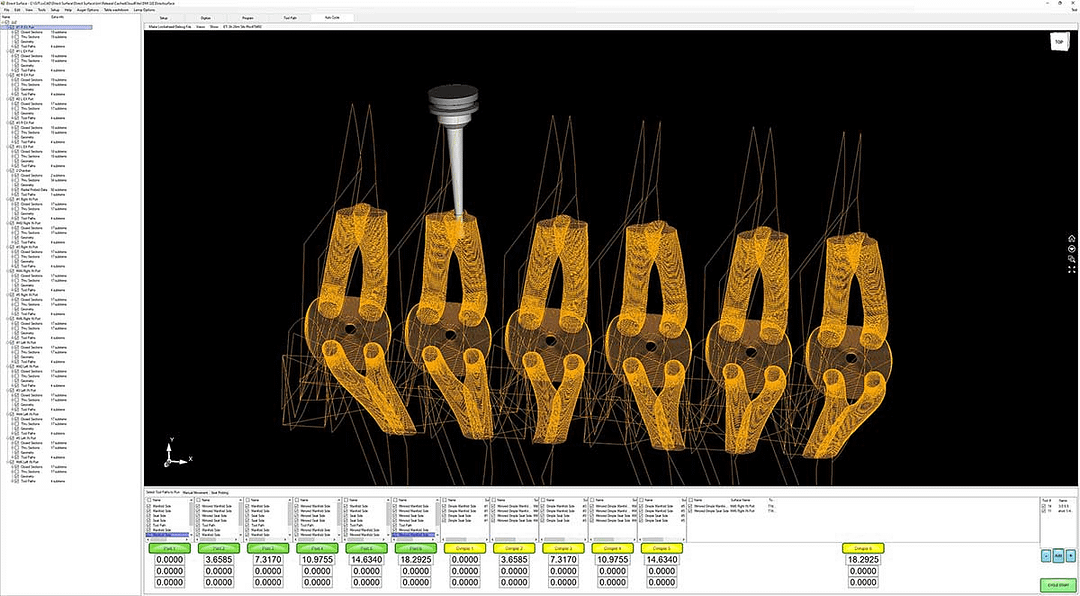

One of the standout features of our next-generation 4C control system is its ability to import CAD models directly into the software. This breakthrough capability allows for effortless conversion of CAD models into toolpaths, which the machine can execute with exceptional precision. Say goodbye to manual programming and tedious calculations – with the EM69HP and 4C Software, you can streamline your workflow and achieve remarkable results.

Unleash Your Creativity with Upgradeable Software

At Rottler, we understand that innovation never stands still. That’s why our 4C Software is designed to be easily upgradeable, ensuring that you always have access to the latest features and functionalities. Stay ahead of the competition by taking advantage of our continuous software updates, which unlock new possibilities and keep your machining center at the forefront of technology.

Furthermore, the Advanced DM software tools integrated into the 4C Software empower you to manipulate port designs and minimize digitizing time. This means you can capture data once and make necessary adjustments to the design, including hand-ported designs, quickly and efficiently. With the EM69HP and 4C Software, unleashing your creativity has never been easier.

Enhanced Efficiency through Networking

In today’s interconnected world, collaboration and efficiency go hand in hand. Our Advanced Optional 4C Software allows you to network your machining center, enabling seamless communication and enhanced productivity. Share data, coordinate projects, and optimize your machining processes like never before, all thanks to the power of networking.

We have more then 100 years of experience

We have more then 100 years of experience

Features

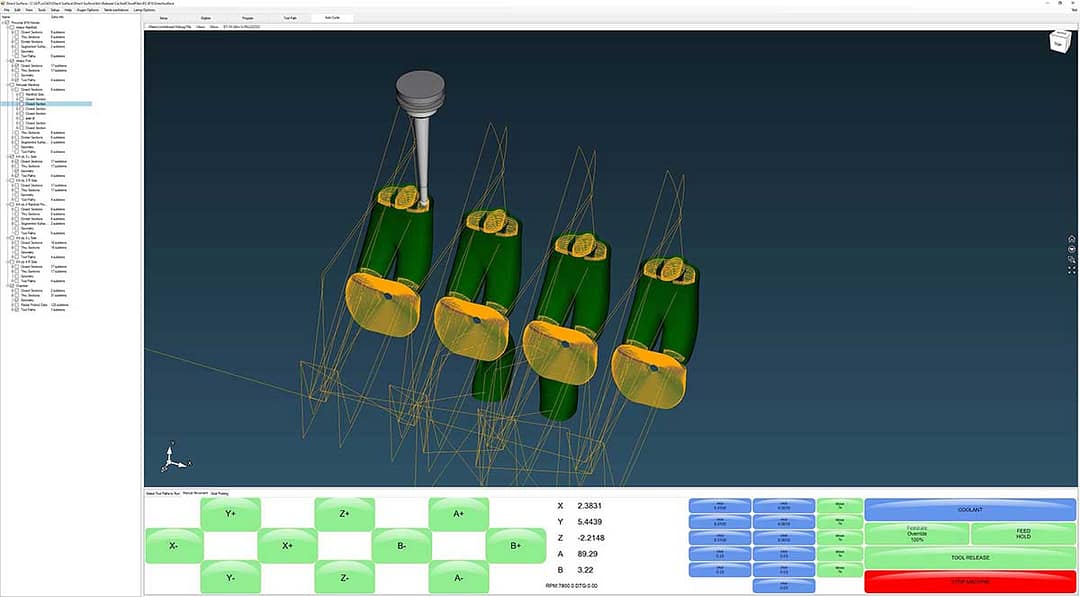

Spindle in 5th Axis – The high torque spindle of the EM69HP is built into the 5th axis of the machine with the center of the cutting tool on the same center as the 5th axis. The spindle is able to tilt 60 degrees to the left and right.

This unique feature allows easier set up and faster porting time compared to fixed spindle machines.

Competitive machines have a fixed spindle and therefore have to tilt the cylinder head left and right which makes complicated programming and each port has to be programmed differently.

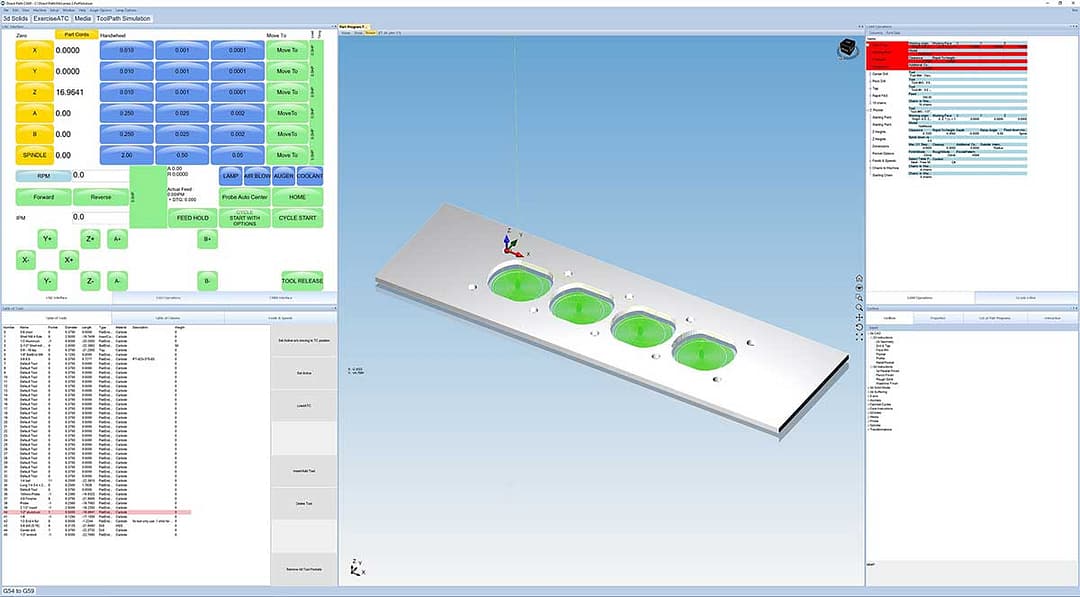

Touch Screen Technology – Rottler utilizes a 32” TOUCH SCREEN to simplify machine control operation. Touch screen allows separate control panels to display only the information and control buttons that are required for that particular operation to be displayed and hide the information and buttons not required. Most CNC machines have large control panels with many unnecessary buttons and this makes learning the machine slow and complicated, which is stressful to a new operator.

Instant Internet Support – Rottler offers cutting edge internet support direct from your machine to the factory. Skype is installed for internet support. This feature gives you instant, direct contact with Rottler right on the machine without even making a phone call.

Automatic Tool Changer – The 24 tool automatic tool changer is included as standard equipment for “set it and forget it” operation.

Pre-Arrival and On-Site Training Available – Rottler offers training videos and guidelines as well as factory training prior to delivery of your EM69HP as well as on-site training after delivery. Rottler’s EM69HP is so easy to learn most operators are on their own within three to five days. Once your EM69HP order is confirmed, a software package including a course of training videos and instruction guidelines will be sent to you so that the operator can start learning the software before the new machine even arrives. Should you feel that extra training is required before the arrival of the machine, Rottler offers optional, additional hands-on factory training.

Simplicity – The simplicity of the complete process from digitizing to programming to actually machining the heads is an important feature. Rottler has developed this system for over 12 years, making the Rottler EM69HP a system that is easy and fast to learn. The EM69HP will start paying for itself by reproducing heads fast within 3 days of training!

Exclusive 4C Control – What is 4C Software? Rottler’s newest EM Series equipment offers Computer Numeric Control (CNC), Computer Aided Design (CAD) and Computer Aided Manufacturing (CAM) in the industry’s most advanced Computer Measuring Machine (CMM). The 4C technology allows users to digitize, edit designs and begin cutting in less time but also requires less machining/programming expertise compared to many other systems. This brand new, revolutionary CNC machine CAD/CAM software allows 3D CAD Solid Models to be imported or created at the machine – the built-in CAM functions can be used to semi automatically and interactively create complex 3D tool paths direct from the CAD geometry.

Unique Features – All-in-one digitizing/probing, programming and porting machine – nothing else required! And it’s all done in one software package. All other systems use 3-5 software programs for each operation, each requires it’s own long learning curve. We do digitizing, surface programming, surface modifications (if need be), toolpath generation and operation of the machine from one common program!

Tooling Packages – Rottler offers complete packages including all necessary software, fixtures, tool holders and porting tools.

Turn-key Package Includes: Machine, software, fixtures and tooling, training (at factory and/or on-site after machine delivery,) internet support (internet connection to the machine computer – can be controlled remotely from anywhere in the world.)

Machine Operations

- 5 Axis CNC Digitizing

- Automatic Tool Changer

- CNC Head Porting

- Cylinder Boring

- Cylinder Head Resurfacing

- Lifter Boring

- Line Boring

- Multi Purpose CNC (Custom Parts)

- Thrust Cutting

Download documentation

Rottler EM103H Standard Equipment

Standard equipment that comes with the Rottler EM69HP Traveling Column Boring Machine:

- High Speed Spindle Motor with increased power 43HP 32kW and speed up to 20,000RPM.

- A 24 tool Automatic Tool Changer is included. Tool changes are accomplished via a dual arm tool changer and rotary tool carousel traveling on linear slides in the Y axis for clearance.

- Optional Software System available for the machine:

- Port and Chamber CAD/CAM software to quickly manipulate port dimensions, view cross section area, calculate volume, create surfaces, create tool paths and machine ports and chambers. Requires CNC program – either ADP-PROBE4 digitizing system or Rottler PATH as detailed below.

- After an order is placed, the training videos on www.RottlerTube.com must be studied before Rottler training technician travels to the machine for onsite training. Operators must continue to view these training videos after training to keep up to date with operation of the control and up to date with the latest features.

- Internet connection to the machine computer must be provided and connected at all times during the use of the machine. This is required for service support. The control sends information to the Rottler service department.

- Customer must have laptop with videocam for software and programming support.

- Highly Interactive & Very Responsive PC Based Single Processor Control System by Direct Motion Control Technology

- Standard Windows User Interface with Animated Training & Remote Diagnostics

- CNC 32″ Touch Screen Control, Windows Operating System with Intel Processor, Networking and Internet Connection included.

- Internet enabled with the ability for a technician to “take over” the machine for remote training and diagnostics from anywhere in the world.

- Programming and Machine Operating through 19″ (500mm) extra bright touch screen.

- Precision Digital Readout, .0001″ (.002mm) Resolution.

- Accuracy ensures Ports will Line Up with No Step – No Hand Blending Required.

- 120 Degree Range of Motion on 5th Axis Tilt.

- Custom Specialized Cutters and Tool Holders Minimize Run Out, Chatter, Noise, Clogging.

- High Spindle Speeds (up to 20,000 RPM) with low speed torque for fast stock removal when machining billet castings and boring engine blocks.

- Linear Roller Bearing Slideway construction on all axes for smooth and precise axis movement.

- Direct Drive Precision Ground Ball Screws on all axes for improvement accuracy and repeatability.

- High Feed Rates of 100 IPM (2.5MPM) with Integrated Design & Sophisticated Look Ahead Software.

- Rotary Vector Gear Reducers in 4th and 5th Axis for extended life and near zero backlash.

- Direct Drive AC Servo Motors on all 5 axis – no belts.

- ABS Brushless AC Servo Motors.

- Linear Motion Slide Way construction for smooth and precise axis feed.

- Fully Enclosed with Sliding Doors and Coolant System with chip auger and roll out coolant tank.

Give us a call, we have all the answers for you.

Rottler EM69HP specifications

| Control | Rottler CNC |

| Spindle - Motor Torque | 80NM |

| Slideway Type (X/Y/Z) | Linear Roller Bearing Slideways |

| Axis Feed Method (X/Y/Z) | Direct Coupled Servo Driven Ball Screw |

| Table - Size | 500 x 1500mm |

| Table - T Slots | 5 |

| Travel - Horizontal (X Axis) | 1000mm |

| Travel - In/Out (Y Axis) | 500mm |

| Travel - Vertical (Z Axis) | 762mm |

| Travel - Spindle Nose to Table | 1016mm |

| Spindle - Taper | CAT40 |

| Spindle - Rotation Speed | 0 to 20000 RPM |

| Coolant Capacity | 320 Liters |

| Weight Capacity | 700kgs |

| 5th Axis Rotation | 120deg (+/- 60 Deg) |

| Feed Rate | 0-2.54mpm |

| Tool Changer - Number of Tools | 24 |

| Tool Changer - Maximum Weight of Tool | 7kgs |

| Tool Changer - Maximum Length of Tool | 300mm |

| Dimensions - Machine | 2827D x 3025W x 2745mm H |

| Dimensions - Floor Space Requirements | 3460D x 4335Wmm |

| Dimensions - Shipping | 2286D x 3073W x 2794mm H |

| Machine Weight | 5546 kg |

| Electrical Requirements | 208-240V, 60A, 50/60Hz, 3Ph |

| Air Requirements | 28 l/min @ 6 bar |

| Paint Color Code | RAL9002 (Grey White) |

Control

The Rottler EM69HP: Revolutionizing CNC Universal Machining

Welcome to the future of machining with the Rottler EM69HP 5-axis CNC universal machining center. This groundbreaking solution offers a comprehensive approach to digitizing, programming, and porting, all in one user-friendly touch screen software. Say goodbye to the complexities of multiple software tools and embrace a streamlined process that saves time and reduces the learning curve.

Efficiency and Precision with Rottler Software

The EM69HP’s advanced software is designed to handle the entire machining process seamlessly. From digitizing to programming and port modification, our intuitive touch screen software empowers operators to effortlessly navigate through each step. With no external software tools required, you can achieve accurate results while eliminating the need for extensive training.

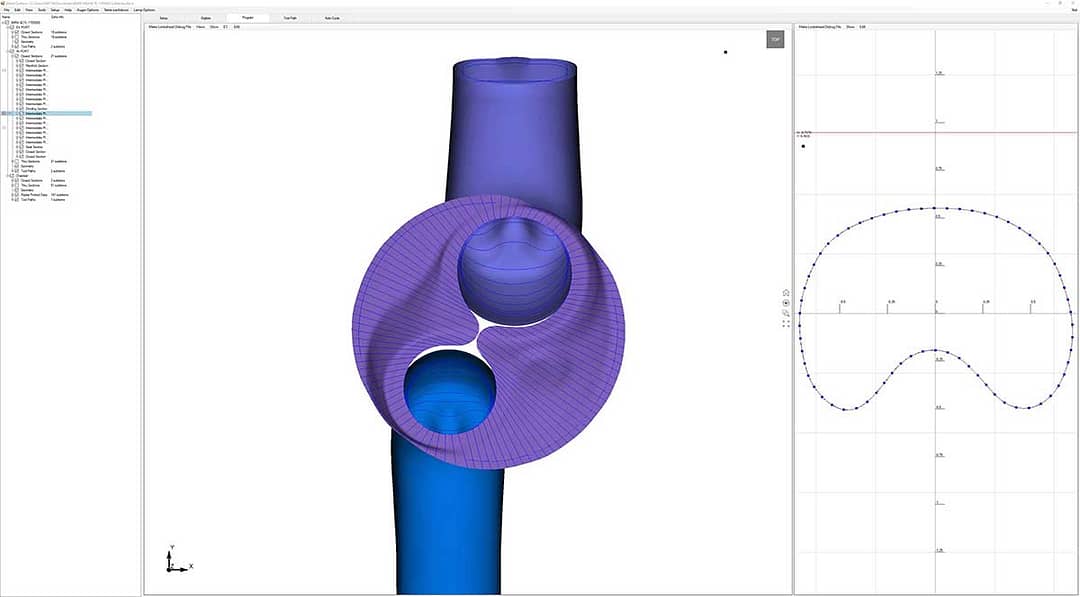

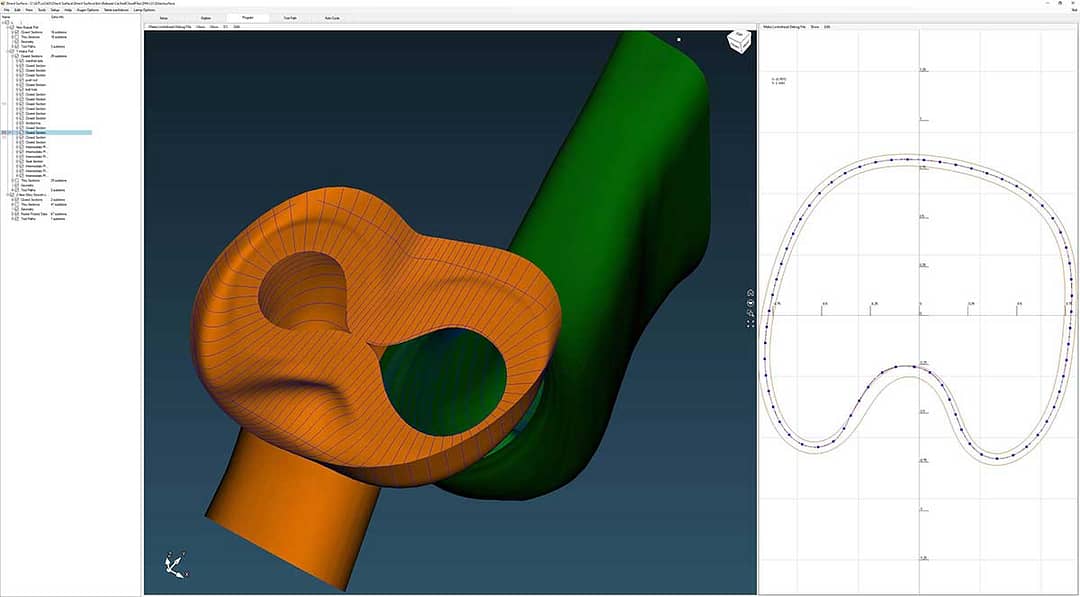

One of the standout features of our software is the ability to view cross-sectional area and measure volume. This powerful capability enables operators to precisely calculate and analyze the dimensions of port areas, ensuring accuracy as port shapes evolve throughout the modification process.

Unlocking the Potential: Digitize, Modify, and Machine

Why rely on manual hand-porting when the EM69HP software can revolutionize your approach? With our innovative digitization capabilities, you can quickly capture the cast head and utilize the software’s port modification tools to refine and enhance the ports digitally. This means you can achieve beautifully machined ports with close tolerances, all without the need for extensive manual labor.

Our advanced Direct Motion software tools provide operators with unparalleled port design manipulation capabilities, reducing digitizing time and facilitating on-screen modifications. With the ability to pick up data once and modify the design directly on the screen, operators have full control over the final port design, even for hand-ported designs that require adjustments.

Seamless Integration and Versatility

Designed to offer maximum flexibility, the EM69HP’s software utilizes standard PC hardware and software. This ensures optimal performance, easy networking, and effortless upgradability and repairability. Our all-inclusive system eliminates the need for transferring design data between different computers or converting data between separate software programs, saving valuable time and eliminating unnecessary hassle.

Moreover, our versatile software allows seamless importing and exporting of designs between the most common CAD/CAM software programs. This means that if you are familiar with programs like Surfcam or Mastercam, you can leverage your previous knowledge and experience, making the transition to the EM69HP seamless and efficient.

Harnessing the Power of the 3D Arc Feature

With the EM69HP’s 3D Arc Feature, operators gain a powerful tool for programming arcs both “through” and “around” the port. This capability is particularly valuable for defining critical shapes in the short turn of a port, allowing for precise mathematical definition and maximum flow development. Operators can make changes to the 3D port in seconds, enabling rapid iterations and optimization.

Experience the future of CNC machining with the Rottler EM69HP. Discover how our advanced software, combined with the machine’s exceptional capabilities, can revolutionize your machining operations.