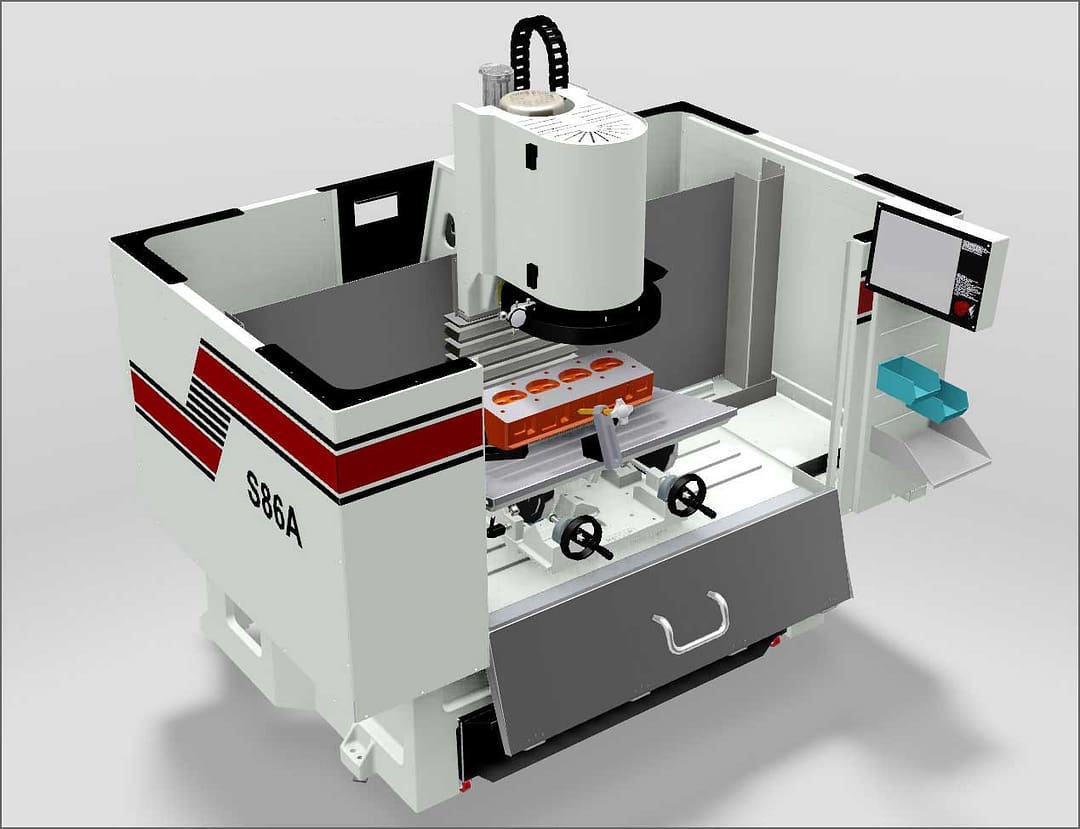

Rottler S86A CNC Automatic Surfacing Machine: Precision and Efficiency Redefined

Looking for a state-of-the-art CNC automatic surfacing machine that combines precision, speed, and reliability? Look no further than the Rottler S86A. With its advanced features and cutting-edge technology, this machine is designed to meet the demands of modern surfacing applications. Whether you’re in the automotive, diesel, or industrial sector, the S86A is a game-changer that will elevate your surfacing capabilities to new heights.

Unparalleled Precision and Accuracy

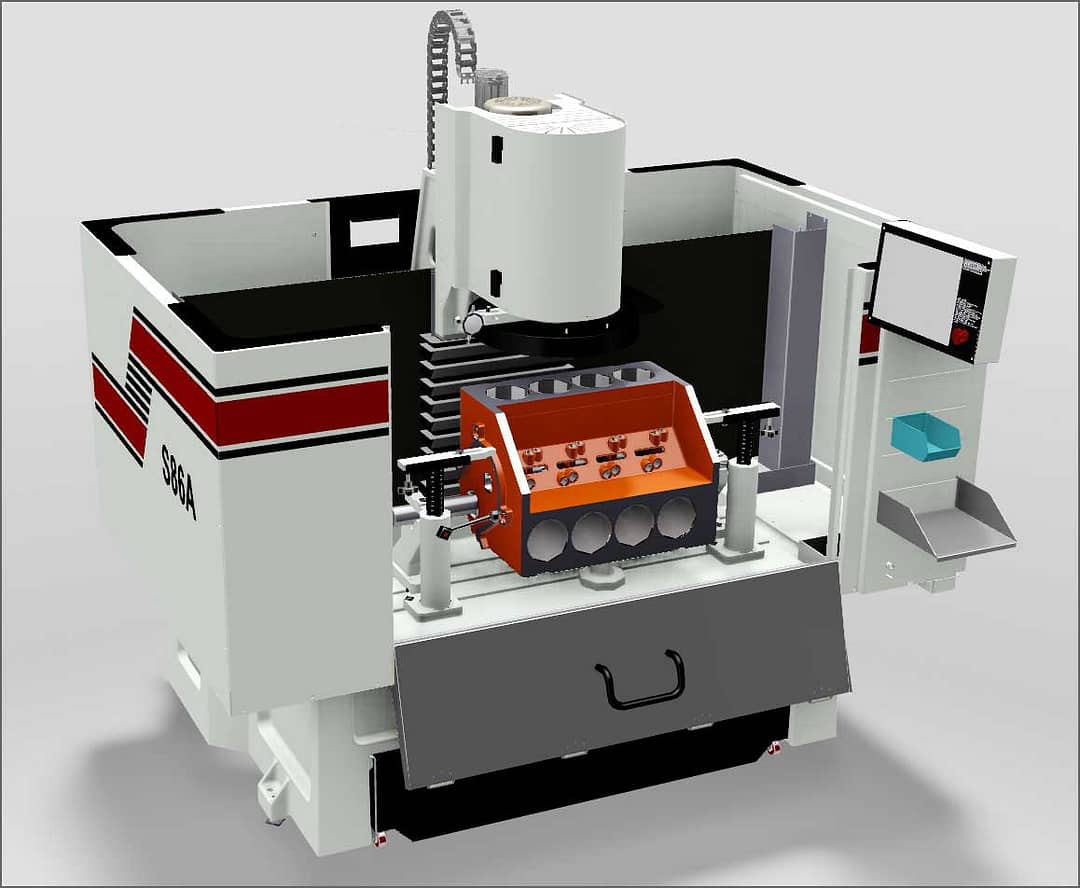

The S86A is engineered to deliver unparalleled precision and accuracy in every surfacing job. Equipped with advanced CNC technology, this machine ensures consistent and precise surfacing results, leaving no room for errors. From cylinder heads to engine blocks, the S86A guarantees a smooth and uniform finish, maximizing performance and efficiency.

With its robust construction and rigid design, the S86A minimizes vibration and maintains stability even during high-speed operations. This stability, combined with the machine’s exceptional accuracy, allows for precise cuts and surface finishes that meet the most demanding specifications.

Efficiency at its Finest

The S86A is not only about precision, but it’s also highly efficient, helping you save time and boost productivity. The machine incorporates advanced automation features that streamline the surfacing process, reducing manual intervention and increasing workflow efficiency.

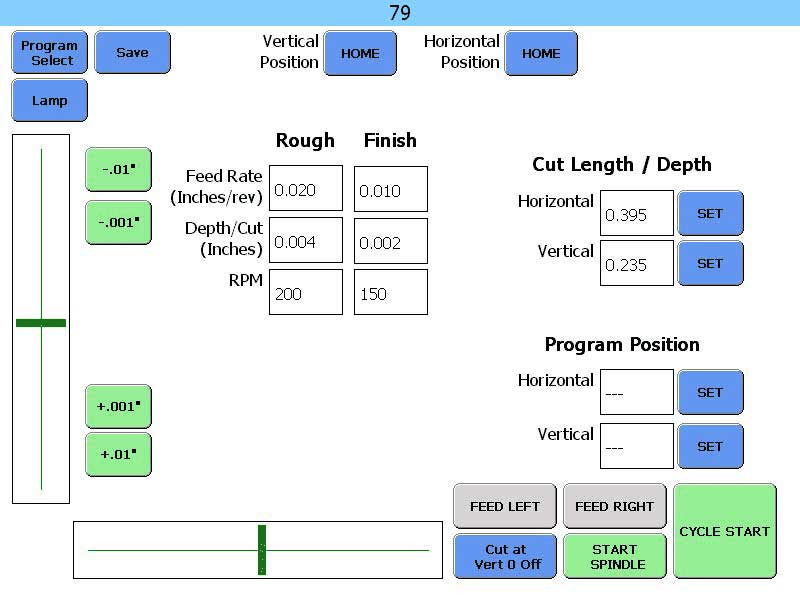

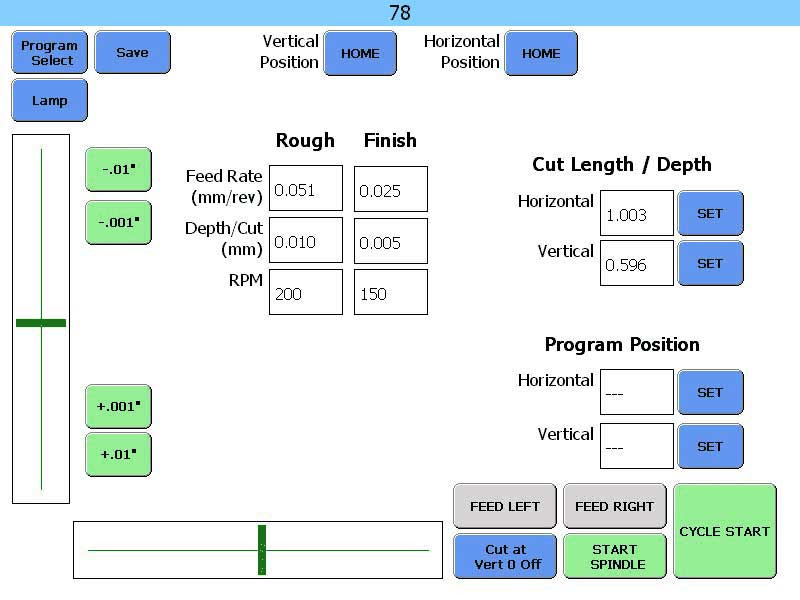

Thanks to its CNC control system, the S86A offers automated surfacing cycles, eliminating the need for constant operator supervision. This not only saves time but also minimizes the risk of human error, ensuring consistent and high-quality results every time. With the S86A, you can optimize your production line and achieve higher output without compromising on quality.

Seamless Integration and User-Friendly Interface

Integrating the S86A into your existing workflow is a breeze. Rottler has designed this machine with versatility in mind, allowing for seamless integration into various surfacing applications. Whether you’re a small workshop or a large-scale manufacturing facility, the S86A adapts to your needs and delivers outstanding results.

The user-friendly interface of the S86A makes operation and programming effortless. The intuitive control panel and touch screen interface provide easy access to all the machine’s features, enabling operators to set up jobs quickly and efficiently. Rottler’s commitment to user experience is evident in the S86A’s interface, ensuring that even less-experienced operators can learn and operate the machine with ease.

Durable and Reliable Construction

Rottler is renowned for its commitment to quality and durability, and the S86A is no exception. Built with robust materials and precision engineering, this machine is designed to withstand the rigors of heavy-duty surfacing operations. The S86A’s solid construction ensures long-term reliability and reduces maintenance requirements, allowing you to focus on your work without worrying about downtime.

Furthermore, Rottler’s dedicated customer support team is always ready to assist you with any questions or concerns you may have. From installation to ongoing technical support, Rottler provides comprehensive assistance to ensure that your S86A operates at its best and delivers optimal performance for years to come.

Discover the power of precision and efficiency with the Rottler S86A CNC Automatic Surfacing Machine. Take your surfacing capabilities to the next level and experience the Rottler advantage. Contact us today to learn more or to schedule a demonstration.

We have more then 100 years of experience

We have more then 100 years of experience

Features

- Latest ClearPath Integrated Servo Control Technology – State of the art electronic controls make the S80 machines the most advanced dry cutting surfacing machines available today.

- Increased Vertical Travel – the workhead is mounted on linear roller bearing slideways and has extended travel 19” (483mm) eliminating the need for parallels while being able to surface a wide variety of jobs from small single cylinder heads to tall diesel blocks.

- Linear Roller Bearing Slideways – the vertical and horizontal movements are by precision ball screens and on linear roller bearing slideways.

- Super Fine Surface Finish – Direct Drive precision ball screws and linear slideways combined with infinitely variable speeds and feeds allows surface finish as low as 2Ra to 6Ra. Today’s MLS (Multi Layer Steel) head gaskets require super fine finish to seal combustion pressure and oil and water.

- Dry Cutting – the spindle and cutterhead system is specially designed and developed for dry cutting with CBN and PCD cutting tools eliminating the need for coolant.

- Chip Collection System – the base casting and machine enclosure is designed to catch chips and direct them down into a roll out chip bin making clean up fast and easy.

- Reduced Floor Space – Traveling Column Design and compact, one piece base castings give the most compact surfacing machines available today reducing floor space requirements.

- Folding Doors – the stainless steel doors fold down for access to the work area and fold up to protect the operator and keep the work area clean of any chips.

- Universal T Slot Base – Large One Piece Mehanite Cast Iron Base with T-Slots allows mounting of any fixture and any job – jacks and clamps can be placed anywhere!

- Program Length of Part – Input length of surface to be machined and the machine travels the exact distance then returns to home – not necessary for time consuming setting of end stops.

- Fast Floor to Floor Time – Heads can be surfaced in a few minutes and a pair of angled V8 heads in less than eight minutes.

Machine Operations

- Block Surfacing

- Cylinder Head Resurfacing

Rottler S86A Standard Equipment

Standard equipment that comes with the Rottler S86A CNC Automatic Surfacing Machine:

- New Technology ClearPath® Integrated Servo System with Touch Screen Control.

- Conversational Touch Screen Control allows simple programming for any workpiece such as depth of cut, multiple passes, total material to be removed, roughing and finishing speeds and feeds.

- No Handwheel required, machine is moved by sliding finger on touch screen slide bars.

- Programmable Rapid Touch Off Set Point for reduced Cycle Times

- On completion of Automatic Cycle, Cutterhead returns to Home Start Position at Vertical Zero Height

- Infinitely Variable Spindle Speeds from 350 – 1,800 RPM for machining different metals

- Infinitely Variable Travel Feeds .001 – .080″ (.025-2mm) per Cutterhead Revolution for Desired Surface Finish Roughness

- Work Head Vertical Travel via Ball Screw and Linear Roller Slideway for Precise Movement

- Maximum Work Head Travel 51″ (1,300mm)

- High Rapid Traverse Rate for Reduced Cycle Time – 200″ (5,080mm) per minute

- Direct Drive Ground Ball Screw for Work Head and Vertical Column Traverse

- Linear Roller Bearing Slideways for Smooth and Precise Movement

- 16″ (420mm) Cutterhead includes 2 radially and axially adjustable cutting insert tool holders for 3/8″ (9.52mm) IC Round or Square inserts (Optional 1/2″ (12.70mm) IC Cutting Insert tool holders available)

- Cutterhead Guard and Slanted Casting with Roll Out Chip Bin for Efficient Chip Collection

- Enclosed Work Area with Quick Folding Door for Easy Access and a Cleaner Work Enviroment

- Depth Dial Indicator Assembly for Rapid Touch Off on Surface to be Machined

- Large One Piece Base Casting with 3 T Slots for Universal Fixture Mounting

- Instruction and Spare Parts Manual

Give us a call, we have all the answers for you.

Rottler S86A specifications

| Control | Automatic CNC |

| Table - Size | 1270 x 508mm |

| Spindle - Rotation Speed | 350 to 1800 RPM |

| Cutter Diameter | 406mm |

| Cutter Travel (Horizontal) | 1346mm |

| Cutter Travel (Vertical) | 483mm |

| Max Distance - Cutting Inserts to Machine Base | 737mm |

| Spindle Feeds Variable | .025-2mm |

| Rapid Travers Rate (per min) | 5080mm |

| Dimensions - Machine | 2189D x 1734W x 1981mm H |

| Dimensions - Floor Space Requirements | 2189D x 1734Wmm |

| Dimensions - Shipping | 1981D x 2362W x 2362mm H |

| Machine Weight | 2268 kg |

| Electrical Requirements | 208-240V, 30A, 50/60Hz, 1Ph |

| Paint Color Code | RAL9002 (Grey White) |

Control

Over four decades ago, Rottler pioneered automation and programming by utilizing electronics and computers. Today, the S80 Series Surfacing Machines incorporate the latest ClearPath Integrated Servo Touch Screen Control Technology into a Dry Surfacing Machine capable of surfacing a wide variety of materials and with features such as multi pass automatic machining. Rottler touch screen control technology make the machine easy and fast to learn and operate.