Discover the Rottler H87AXY: Precision Engine Machining at Its Finest

Welcome to Rottler Machines Europe, your premier destination for cutting-edge automotive machining solutions. If you’re in search of a high-performance engine equipment that delivers outstanding results, look no further than the Rottler H87AXY. Designed to meet the demanding needs of European automotive professionals, this machine sets new standards in precision and efficiency.

The Rottler H87AXY: Unleashing Engine Block Machining Excellence

At Rottler Machines Europe, we understand the importance of superior engine block machining in today’s competitive market. That’s why we’ve engineered the Rottler H87AXY to provide unmatched quality and performance. Whether you’re looking to rebuild an engine or enhance its capabilities, this machine is the ultimate tool for the job.

Equipped with advanced cylinder head surfacing technology, the Rottler H87AXY ensures unparalleled accuracy in every cut. Its precision honing capabilities enable you to achieve the perfect finish, resulting in enhanced engine performance and longevity. Say goodbye to subpar machining and welcome a new era of automotive excellence.

Unrivaled Automotive Machining Solutions for Europe

As a trusted name in the industry, Rottler Machines Europe is committed to providing European automotive professionals with the most reliable and durable equipment available. Our engine rebuilding solutions are designed to meet the unique challenges faced by mechanics, engine builders, and performance enthusiasts across the continent.

With our heavy-duty machining technology, you can confidently tackle even the most demanding projects. The Rottler H87AXY empowers you to optimize engine performance, increase horsepower, and unlock the full potential of every vehicle that comes your way. Trust in Rottler Machines Europe to deliver the tools you need to surpass customer expectations and stay ahead of the competition.

Experience the Rottler Advantage Today

When it comes to engine machining, the Rottler H87AXY is the epitome of excellence. Its precision, reliability, and efficiency make it the go-to choice for European automotive professionals who demand the best. Take your engine rebuilding capabilities to new heights and explore the full potential of the Rottler H87AXY.

Contact Rottler Machines Europe today to learn more about this remarkable machine and how it can revolutionize your engine machining processes. Our knowledgeable team is ready to provide expert guidance and support, ensuring that you make the most informed decision for your business. Join the ranks of satisfied Rottler customers across Europe and experience the future of precision engine machining.

We have more then 100 years of experience

We have more then 100 years of experience

Features

Revolutionize Engine Machining with the Rottler H87AXY: The Ultimate High-Production Machine

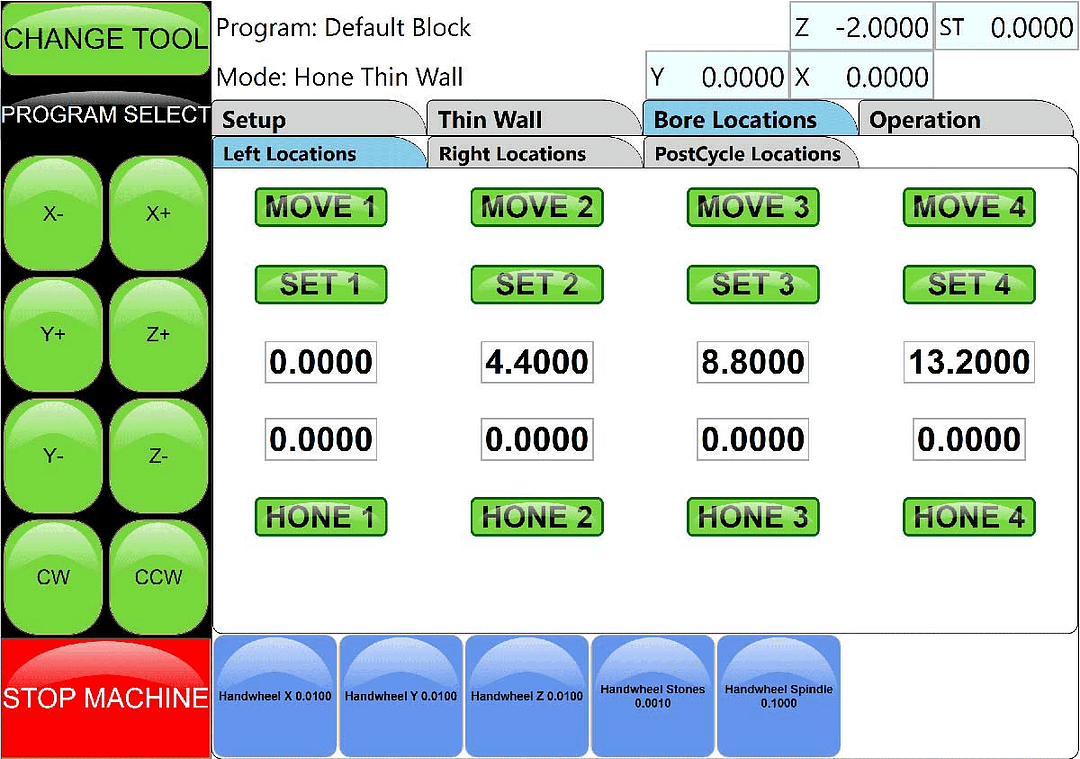

Welcome to Rottler Machines Europe, where cutting-edge automotive machining solutions meet unrivaled precision and efficiency. Introducing the special version Rottler H87AXY, a high-production machine designed to automate the honing process for offset cylinder blocks and parts. With its automatic movement in both the X and Y axes, this machine takes engine machining to a whole new level.

Automatic Honing Offset: Unlocking Efficiency and Precision

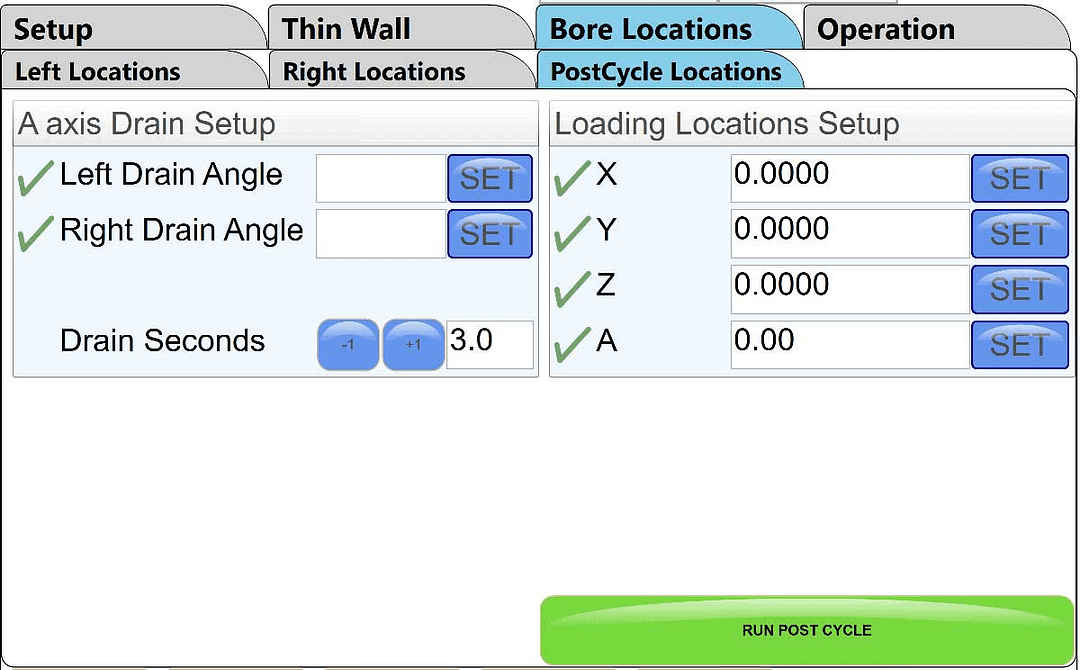

Imagine the convenience of a machine that can automatically hone offset cylinder blocks and parts, all with a simple set-up. The Rottler H87AXY makes it possible. Its special feature allows for the use of an optional programmable roll-over fixture, enabling complete V block honing automatically and unattended. Say goodbye to manual honing and hello to increased productivity and precision.

Effortless Coolant Drainage: Streamlined Operations

No more hassle when it comes to draining coolant out of the block at the end of the cycle. The Rottler H87AXY has you covered. With its built-in feature, coolant drainage becomes a breeze, minimizing downtime and streamlining your operations. Focus on what matters most – delivering exceptional engine machining results.

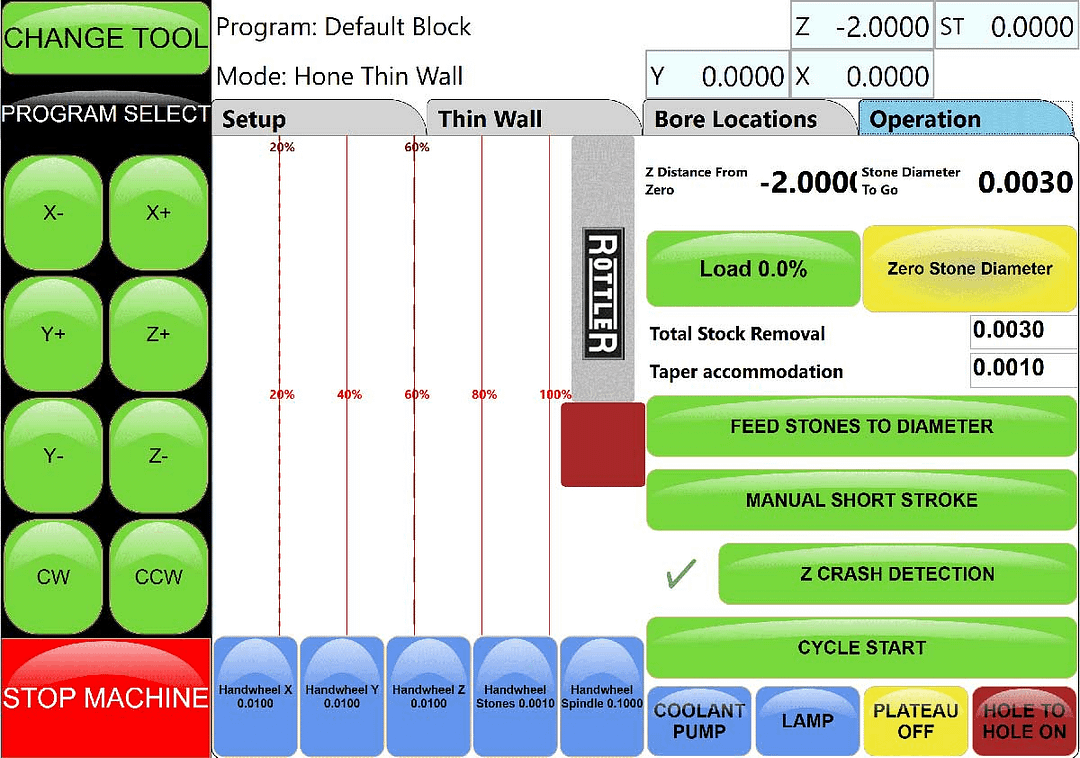

Automatic Lower Crash Protection System: Safeguarding Your Investment

Engine blocks often pose interference challenges in the lower area of the bores, which can lead to damage to honing stones and holders. The Rottler H87AXY’s automatic lower crash protection system eliminates this risk. Prior to rotation and stroking motion, the machine intelligently checks for bore interference, ensuring that honing stones and holders are safeguarded from potential damage. Enjoy peace of mind knowing that your equipment is protected and your operations can run smoothly.

Unleashing Power and Precision: Rottler H87AXY Control

The heart of the Rottler H87AXY lies in its advanced control system. Designed to sense variances in lower bores, the H87X Control guarantees optimal performance. By starting the stroking motion at full power only when interference is avoided, this intelligent system eliminates any chance of stone or holder damage. Experience the power and precision of the Rottler H87AXY, and take your engine machining to new heights.

Unlock the full potential of high-production engine machining with the Rottler H87AXY. Contact Rottler Machines Europe today to learn more about this game-changing machine and how it can revolutionize your operations. Our team of experts is ready to assist you in making the right choice for your business. Stay ahead of the competition and elevate your engine machining capabilities with Rottler Machines Europe.

Machine Operations

- Cylinder Honing

- Liner Honing

Rottler H87AXY Standard Equipment

Standard equipment that comes with the Rottler H87AXY CNC Automatic Vertical Honing Machine with Hole-to-Hole Automation:

- Special Heavy Duty Version High Production Machine that can move automatically in both X and Y axis for automatic honing offset cylinder blocks.

- Automatic Lower Crash Protection System – every time cycle start is activated, the machine will check that the stones will not interfere with lower bore before starting rotation and stroking preventing stone and stone holder damage.

- Spindle Taper with Quick Change System – change hone heads in seconds without any wrenches

- Automatic Honing Stone retract at End of Cycle – the machine will automatically retract the stones during last stroke so that the stones do not leave any scratches or marks in the bore.

- Automatic Cross Hatch Angle System – the machine will automatically adjust parameters to programmed cross hatch angle and finish the bore to programmed angle.

- Automatic Roughing and Finishing Load Sensing System – machine controls load/pressure that the honing stones exert against the cylinder wall and reduces load during finishing cycle.

- Automatic Short Stroke and Dwell – machine detects tight area and short stroke or dwells.

- Automatic Stone Feed-out System – once hone head is positioned in the bore, the machine automatically expands stones and rotates slowly before starting hone cycle

- Automatic Plateau Finish Program – the machine automatically expands plateau stones/brushes to programmed load and counts down number of plateau strokes, then withdraws the stones/brushes and retracts the hone head to the clearance position.

- Control and programming through 15″ (400mm) CNC Touch Screen Control

- Precision Display in .0001″ (.002mm) resolution

- Industrial PC with Windows Operating System

- WiFi Adapter, USB Flash Drive, and Headset

- Remote training, service and support via internet – internet connection to machine required

- Operation in either American or Metric systems

- Horizontal Movement (X Axis)

- Left and Right Direction – 38″ (965mm) – movement is manually on linear slideways

- Horizontal Movement (Y Axis) Front and Back Direction – 5″ (127mm) – movement is on linear slideways and is powered by servo motor.

- Vertical Movement (Z Axis) Up and Down – 40″ (1016mm) – movement is on linear slideways and is powered by servo motor. Special version machine with increased stroke length is available – price on application.

- Stroking System CNC SERVO Controlled High Pitch Ball Screw System

- Infinitely Variable Stroke Speed Control – Variable from 0 to 1500IPM (38m/min)

- Rapid Stroke System Acceleration – 250in/sec (6.35m/sec)

- Spindle Rotation System – CNC SERVO Controlled High Torque Spindle Rotation System – 88 ft.lbs (120NM)

- Infinitely Variable Spindle RPM Control – Variable from 0 to 200RPM

- (2) Stone Trays for up to 6 stone holder sets with built-in Dial Bore Gage Holder

- Hone Head Storage Rack for up to 5 Hone Heads

- Coolant System Large Capacity coolant tank 70 Gal (265 Liter) – tank is located under the machine on wheels and rolls out for servicing from front or rear of machine

- Magnetic system for primary filtering inside coolant tank. Magnets are removable for easy tank cleaning once tank is removed from under the machine

- Lifetime Magnetic Canister Filter System includes tools for cleaning filter.

- Replacable Cartridge Canister Filter System. Dual Gradient 50-5 Micron replacement filter cartridge keeps coolant and cabinet clean. Filter Cartridge 514-2-42C

- Machine Cabinet finished in Baked Enamel Power Coated for easy cleaning and appearance

- Operation, Programming and Spare Parts Manual – Digital

- Paint Color Code: RAL9002 (Grey White)

- Electrical requirements: 205-250V, 30A, 50/60Hz, 3Ph

- Shipping weight 3700 lbs. (1,681 kg)

- Shipping dimensions: 67 X 87 X 100″ H (1702 X 2210 X 2540mmh)

Give us a call, we have all the answers for you.

Rottler H87AXY specifications

| Control | CNC Touch Screen |

| Diameter Range | 48.16-355 - Xmm |

| Workpiece Capacity - Length | 1400mm |

| Torque at Hone Head | 265NM |

| Stroker Motor Torque | 40NM |

| Stroke System Acceleration | 5m/sec2 |

| Spindle - Motor Torque | 53NM |

| Spindle Stroke Speed | 0-38m/min |

| Stroker Motor Power | 2.47KW |

| Travel - Horizontal (X Axis) | 965mm |

| Spindle - Rotation Speed | 1 to 400 RPM |

| Spindle - Motor | 2.77 Kw |

| Coolant Capacity | 265 Liters |

| Maximum Length of Cylinder | 965mm |

| Stroke Length | 1016mm |

| Dimensions - Shipping | 1372D x 1829W x 2896mm H |

| Machine Weight | 1814 kg |

| Electrical Requirements | 208/240V, 30A, 50/60Hz, 3/1Ph |

| Paint Color Code | RAL9002 (Grey White) |

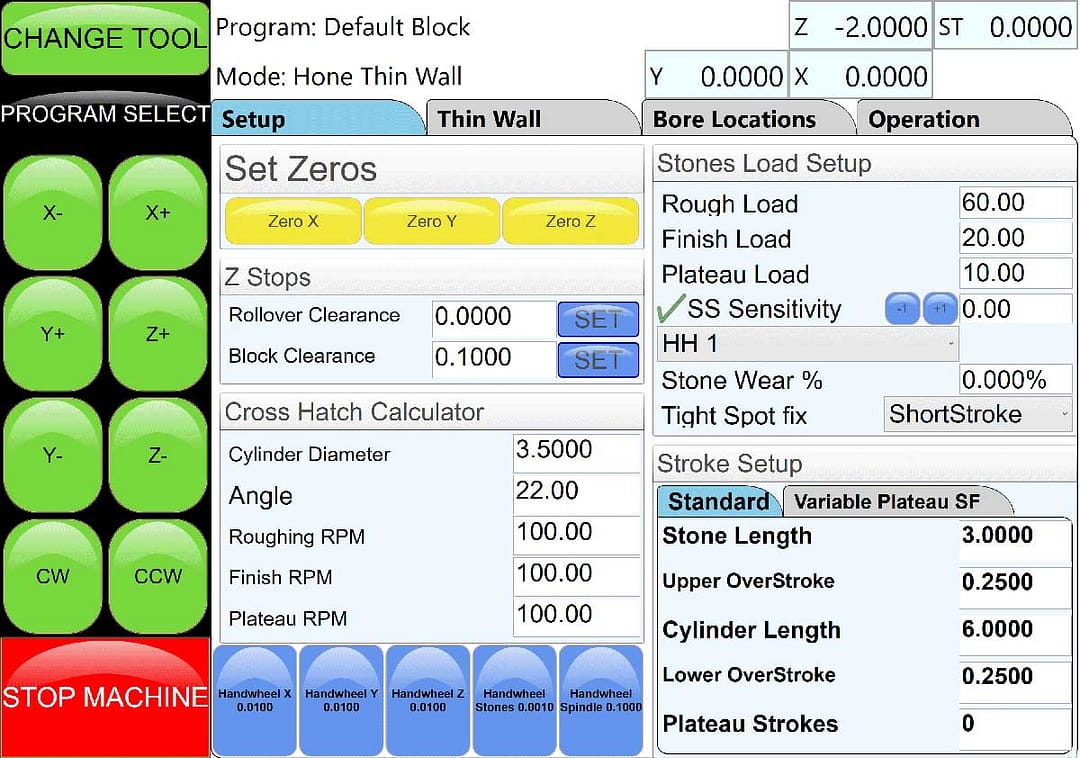

Simplify Your Operations with Rottler Software: Intuitive and Conversational

At Rottler, we understand the importance of simplicity in software design. That’s why our Rottler Software is thoughtfully crafted with user-friendliness in mind. With its conversational interface, operators can swiftly and effortlessly learn and create their own programs, enhancing efficiency and reducing training time.

Creating a new program for a new block is a breeze with Rottler Software. In just a matter of minutes, operators can generate a customized program tailored to specific requirements. Once created, the program is conveniently saved for future recall and repeated use, saving valuable time and effort.

Discover the Power of Conversational Software

Rottler Software’s conversational nature is a game-changer for operators. It eliminates the need for complex programming languages or extensive coding knowledge. Instead, the software guides users through a user-friendly interface, enabling them to interact naturally and intuitively with the system.

With conversational software, operators can quickly grasp the functionalities and confidently navigate through the program creation process. This approach empowers them to take control and adapt to evolving manufacturing needs with ease.

Efficiency and Flexibility at Your Fingertips

By leveraging Rottler Software, operators can optimize their workflow and streamline production processes. The simplicity and speed of program creation enable faster setup times, minimizing downtime and maximizing productivity.

The ability to save and recall programs ensures consistency and eliminates the need to recreate programs from scratch for similar blocks. This feature enhances flexibility, allowing operators to seamlessly switch between different projects and efficiently manage varying production requirements.

Unlock Your Programming Potential

With Rottler Software, operators are not limited by programming complexities. By providing a user-friendly environment, our software empowers individuals to tap into their programming potential and take charge of their machining processes.

Experience the simplicity and power of Rottler Software. Elevate your operations, reduce training time, and boost productivity. Contact us today to learn more about how our intuitive and conversational software can transform your manufacturing workflows.