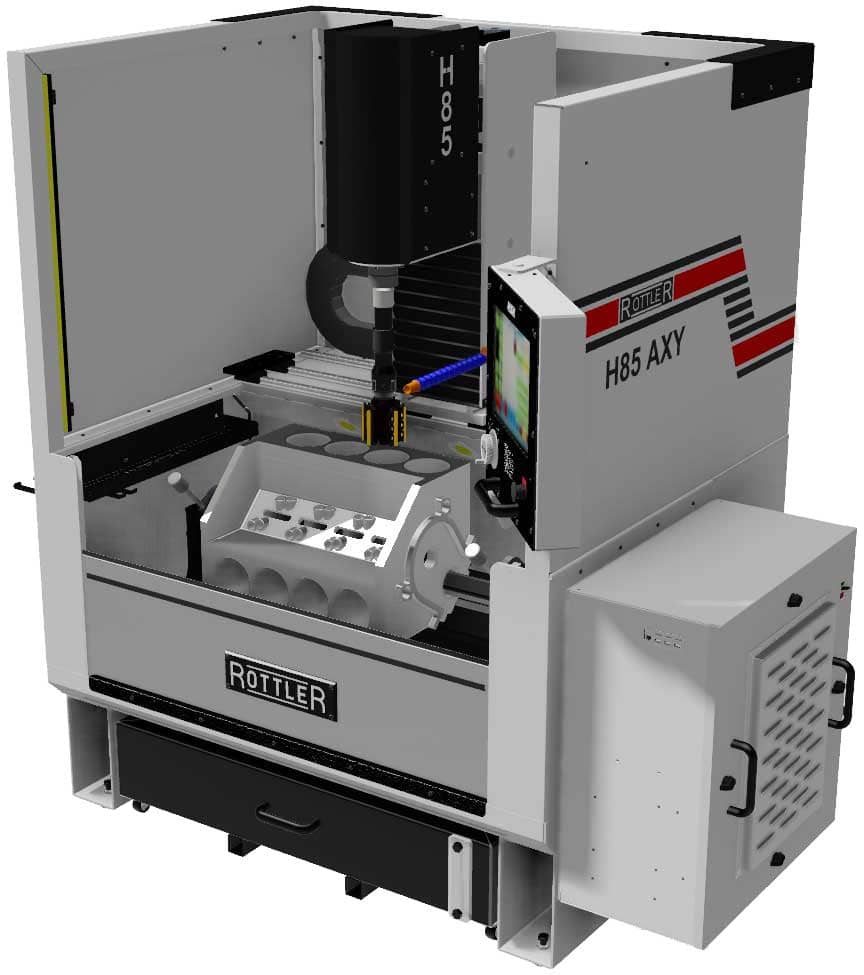

Rottler Machines Europe – Rottler H85AXY: Precision Honing Solutions for European Industries

Are you searching for a reliable CNC vertical honing machine in Europe? Look no further than Rottler Machines Europe! Our advanced Rottler H85AXY model is designed to deliver exceptional honing performance and meet the unique needs of industries across Europe.

The Rottler H85AXY: Unparalleled Precision and Versatility

At Rottler Machines Europe, we understand the importance of precision and efficiency in the honing process. That’s why we developed the Rottler H85AXY, a state-of-the-art CNC vertical honing machine that combines advanced technology with European craftsmanship.

With its cutting-edge features and robust construction, the Rottler H85AXY offers unmatched precision and versatility for a wide range of applications. Whether you need to hone small engine blocks or large industrial components, this machine can handle the task with ease.

Advanced Features and Specifications

The Rottler H85AXY comes equipped with a host of advanced features that make it a top choice for European industries. Its high-resolution touch screen interface allows for intuitive control and easy programming, ensuring precise and consistent honing results every time.

With its CNC-controlled X, Y, and Z axes, the Rottler H85AXY provides exceptional accuracy and repeatability, even when working on complex workpieces. The machine’s powerful spindle motor and variable stroking speed further enhance its honing capabilities, allowing for efficient material removal and superior surface finish.

Benefits of the Rottler H85AXY

Investing in the Rottler H85AXY can bring numerous benefits to your European business. By harnessing the power of this advanced honing machine, you can:

- Achieve precise dimensional control and tight tolerances

- Increase productivity and reduce cycle times

- Enhance surface finish quality

- Optimize workflow and streamline operations

- Improve overall efficiency and profitability

Trust Rottler Machines Europe for Your Honing Needs

When it comes to honing solutions in Europe, Rottler Machines Europe is the name you can trust. Our commitment to quality, innovation, and customer satisfaction sets us apart from the competition.

With our extensive industry experience and in-depth knowledge of the European market, we understand the unique challenges you face. That’s why we offer not only top-of-the-line honing machines like the Rottler H85AXY but also comprehensive after-sales support, including training, service, and spare parts.

Take your honing capabilities to new heights with the Rottler H85AXY. Contact Rottler Machines Europe today to learn more about our products and how we can help your European business thrive.

We have more then 100 years of experience

We have more then 100 years of experience

Features

High Production Honing Machine: Rottler H85AXY – Unattended Honing with Automatic X and Y Axis Movement

Introducing the Rottler H85AXY, a special version high production honing machine designed to revolutionize your honing process. This advanced machine features automatic movement in both the X and Y axis, allowing for efficient honing of offset cylinder blocks and parts without manual intervention.

One of the standout features of the Rottler H85AXY is its optional programmable roll-over fixture, enabling automatic honing of complete V blocks. With this innovative capability, you can save time and streamline your honing operations, as the machine works unattended.

Another noteworthy feature of the Rottler H85AXY is its automatic lower crash protection system. Many engine blocks have interference in the lower area of the bores, which can potentially damage honing stones and holders. However, with the H85AXY, you can say goodbye to such concerns.

The H85AXY’s intelligent control system constantly monitors the bores for interference before initiating the rotation and stroking motion. By starting at full power only when there is no risk of stone or holder damage, the machine ensures a smooth and worry-free honing process.

Furthermore, the Rottler H85AXY includes a feature that drains coolant out of the block at the end of each cycle. This thoughtful addition simplifies the maintenance process and helps maintain a clean working environment.

Experience the Benefits of the Rottler H85AXY

The Rottler H85X offers a range of benefits that will elevate your honing operations:

- High production capacity for efficient and fast honing

- Automatic movement in both X and Y axes for precise honing of offset cylinder blocks and parts

- Programmable roll-over fixture for automatic honing of complete V blocks

- Automatic lower crash protection system to prevent damage to honing stones and holders

- Intelligent control system that detects and avoids interference in lower bores

- Convenient coolant draining feature for easier maintenance

Choose Rottler for Your Honing Needs

When it comes to high-quality honing machines, Rottler is a name you can trust. With the Rottler H85X, we continue to deliver innovative solutions that cater to the specific needs of the industry.

Our commitment to excellence, advanced technology, and unmatched customer support sets us apart from the competition. Whether you’re a seasoned professional or a novice honing enthusiast, the Rottler H85X will empower you to achieve exceptional honing results with ease.

Invest in the Rottler H85X and take your honing capabilities to new heights. Contact us today to learn more about this incredible machine and how it can transform your honing operations.

Machine Operations

- Cylinder Honing

- Liner Honing

Rottler H85AXY Standard Equipment

Standard equipment that comes with the Rottler H85AXY CNC Automatic Vertical Honing Machine with Hole-to-Hole Automation and Optional Block Roll Over:

- Automatic Lower Crash Protection System – every time cycle start is activated, the machine will check that the stones will not interfere with lower bore before starting rotation and stroking preventing stone and stone holder damage.

- Spindle Taper with Quick Change System – change hone heads in seconds without any wrenches

- Automatic Honing Stone retract at End of Cycle – the machine will automatically retract the stones during last stroke so that the stones do not leave any scratches or marks in the bore.

- Automatic Cross Hatch Angle System – the machine will automatically adjust parameters to programmed cross hatch angle and finish the bore to programmed angle.

- Automatic Roughing and Finishing Load Sensing System – machine short strokes or dwells anywhere it senses a tight area.

- Electronic Hand Wheel for lowering hone head into each bore

- Automatic Stone Feed-out System – once hone head is positioned in the bore, the machine automatically expands stones and rotates slowly before starting hone cycle

- Automatic Plateau Brush Finish Program – the machine automatically expands plateau brushes to programmed load and counts down number of plateau strokes, then withdraws the brushes and retracts to the clearance position.

- Control and programming through 15″ (400mm) CNC Touch Screen Control

- Precision Display in .0001″ (.002mm) resolution

- Industrial PC with Windows Operating System

- USB Flash Drive and port for file transfer

- Remote training, service and support via internet connection to machine (required)

- Operation in either American or Metric systems

- Horizontal Movement (X Axis) – Left and Right Direction – 38″ (965mm) – movement is on linear slidways and is powered by servo motor

- Horizontal Movement (Y Axis) – Front and Back Direction – 3″ (75mm) – movement is on linear slideways and is powered by servo motor.

- Vertical Movement (Z Axis) – Up and Down – 19″ (483mm)

- Stroking System – CNC SERVO Controlled High Pitch Ball Screw System

- Infinitely Variable Stroke Speed Control – Variable from 0 to 1500IPM (38m/min)

- Rapid Stroke System Acceleration – 250in/sec (6.35m/sec)

- Spindle Rotation System – CNC SERVO Controlled High Torque Spindle Rotation System – 44 ft.lbs (60NM)

- Infinitely Variable Spindle RPM Control – Variable from 0 to 400RPM

- (2) Stone Trays for up to 6 stone holder sets with built-in Dial Bore Gage Holder

- Hone Head Storage Rack for up to 5 Hone Heads

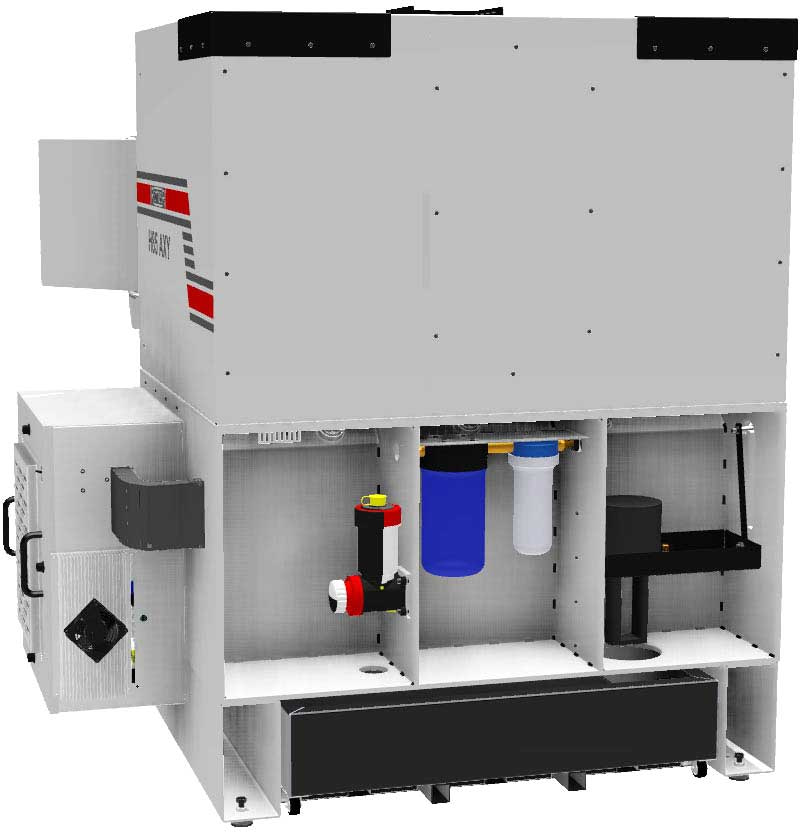

- Coolant System – Large Capacity coolant tank 70 Gal (265 Liter) – tank is located under the machine on wheels and is removable for servicing from front or rear of machine

- Magnetic system for primary filtering inside coolant tank. Magnets are removable for easy tank cleaning once tank is removed from under the machine

- Lifetime Magnetic Canister Filter System includes tools for cleaning filter.

- Replacable Cartridge Canister Filter System. Dual Gradient 50-5 Micron replacement filter cartridge keeps coolant and cabinet clean. Filter Cartridge 514-2-42C

- Machine Cabinet finished in Baked Enamel Power Coated for easy cleaning and appearance

- Operation, Programming and Spare Parts Manual – Digital

- Paint Color Code: RAL9002 (Grey White)

- Electrical requirements: 208/240V, 30A, 50/60Hz, 3Ph

- Shipping weight 2300 lbs. (1,043 kg)

- Shipping dimensions: 60 X 72 X 93″ H (1524 X 2210 X 2337mm)

Give us a call, we have all the answers for you.

Rottler H85AXY specifications

| Control | CNC Touch Screen |

| Diameter Range | 48.16-187 - Xmm |

| Workpiece Capacity - Length | 1400mm |

| Torque at Hone Head | 265NM |

| Stroker Motor Torque | 40NM |

| Stroke System Acceleration | 5m/sec2 |

| Spindle - Motor Torque | 53NM |

| Spindle Stroke Speed | 0-38m/min |

| Stroker Motor Power | 2.47KW |

| Travel - Horizontal (X Axis) | 965mm |

| Spindle - Rotation Speed | 1 to 400 RPM |

| Spindle - Motor | 2.77 Kw |

| Coolant Capacity | 265 Liters |

| Maximum Length of Cylinder | 432mm |

| Stroke Length | 483mm |

| Dimensions - Shipping | 1854D x 2362W x 2362mm H |

| Machine Weight | 1678 kg |

| Electrical Requirements | 208/240V, 30A, 50/60Hz, 3/1Ph |

| Paint Color Code | RAL9002 (Grey White) |

Simplify Your Operations with Rottler Software: Intuitive and Conversational

At Rottler, we understand the importance of simplicity in software design. That’s why our Rottler Software is thoughtfully crafted with user-friendliness in mind. With its conversational interface, operators can swiftly and effortlessly learn and create their own programs, enhancing efficiency and reducing training time.

Creating a new program for a new block is a breeze with Rottler Software. In just a matter of minutes, operators can generate a customized program tailored to specific requirements. Once created, the program is conveniently saved for future recall and repeated use, saving valuable time and effort.

Discover the Power of Conversational Software

Rottler Software’s conversational nature is a game-changer for operators. It eliminates the need for complex programming languages or extensive coding knowledge. Instead, the software guides users through a user-friendly interface, enabling them to interact naturally and intuitively with the system.

With conversational software, operators can quickly grasp the functionalities and confidently navigate through the program creation process. This approach empowers them to take control and adapt to evolving manufacturing needs with ease.

Efficiency and Flexibility at Your Fingertips

By leveraging Rottler Software, operators can optimize their workflow and streamline production processes. The simplicity and speed of program creation enable faster setup times, minimizing downtime and maximizing productivity.

The ability to save and recall programs ensures consistency and eliminates the need to recreate programs from scratch for similar blocks. This feature enhances flexibility, allowing operators to seamlessly switch between different projects and efficiently manage varying production requirements.

Unlock Your Programming Potential

With Rottler Software, operators are not limited by programming complexities. By providing a user-friendly environment, our software empowers individuals to tap into their programming potential and take charge of their machining processes.

Experience the simplicity and power of Rottler Software. Elevate your operations, reduce training time, and boost productivity. Contact us today to learn more about how our intuitive and conversational software can transform your manufacturing workflows.