Rottler F10A Automatic Boring and Sleeving Machine

Are you in search of a reliable and high-performance boring and sleeving machine for your engine cylinder needs? Look no further than the Rottler F10A Automatic Boring and Sleeving Machine. With its advanced features and precision engineering, the F10A is designed to meet the demands of automotive professionals and engine enthusiasts alike.

Engine Boring Made Effortless

The Rottler F10A is at the forefront of engine boring technology, providing unparalleled precision and efficiency. Engineered with cutting-edge automation, this machine simplifies the boring process, saving you valuable time and effort.

Equipped with state-of-the-art CNC controls, the F10A ensures precise and consistent results with every operation. Its powerful spindle motor and rigid construction allow for fast and accurate material removal, enabling you to achieve the desired bore diameter and surface finish with ease.

Revolutionary Sleeving Capabilities

When it comes to engine sleeving, the Rottler F10A stands head and shoulders above the competition. With its innovative design and versatile functionality, it caters to a wide range of sleeving requirements.

Thanks to its advanced sleeve centering system and adjustable tooling options, the F10A delivers exceptional accuracy and concentricity during the sleeving process. Whether you need to repair damaged cylinders or upgrade your engine for enhanced performance, this machine ensures a perfect fit every time.

Precision, Reliability, and Durability

At Rottler Manufacturing, we understand the importance of quality and durability in a boring and sleeving machine. That’s why the F10A is built to withstand the toughest machining tasks while maintaining its precision and reliability.

Our commitment to excellence is evident in every aspect of the F10A’s design. From its robust cast iron construction to its cutting-edge tooling systems, we’ve spared no expense in creating a machine that will exceed your expectations and stand the test of time.

Unlock Your Engine’s Potential

With the Rottler F10A Automatic Boring and Sleeving Machine, you have the power to unlock your engine’s full potential. Whether you’re a professional engine builder or a passionate enthusiast, this machine empowers you to achieve optimal performance and reliability.

Visit our USA website to learn more about the F10A and explore our comprehensive range of engine machining solutions. Experience the Rottler difference and take your engine boring and sleeving capabilities to new heights.

We have more then 100 years of experience

We have more then 100 years of experience

Features

Featues of the Rottler F10A Automatic Boring and Sleeving Machine:

- Speed – All FA Boring Bar models have the same high performance AC servo motor. Independent feed control allows you to change the feed rate from .001″ (.025mm) to .012″ (.3mm) per revolution.

- Accuracy – The FA series uses a precision ground ball screw to control feed rate and cutter position. This allows the machines to repeat cutter position accuracy to .0002″ (.005mm).

- Strength – The Rottler proven spindle and bearing design gives you a rigid machine capable of making heavy sleeve cuts for a lifetime. The F10A has increased spindle size to ensure the best possible bore geometry at high spindle speeds.

- Flexibility – With variable feed rates you are able to maximize the performance of the machine. Increase spindle feed rates for simple oversize bores. Decrease feed rates for sleeve cuts or counter bores. The F10A machines can bore from 1.5″ (38mm) to 9″ (230mm). Special carbide tools are available for counterboring, chamfer cutting, offset boring, and O-ringing.

- Reliability – The F Series machines use a high-speed, cogged belt drive system. This and the use of two independent motors to run the spindle speed and feed, entirely eliminates the gear box.

- Cost Savings – The high speed Rottler FA Boring Bar series machine can bore a block in half the time that other boring machines require. New insert technology is producing long lasting, inexpensive inserts which are capable of handling these high speed and feed rates, with the same cost per insert as previous styles. Inserts do not require sharpening and the low cost of these tools makes them the ultimate choice for boring cylinders.

Machine Operations

- Boring & Sleeving

- Connecting Rod Boring

- Cylinder Boring

- Multi Purpose CNC (Custom Parts)

Rottler F10A Standard Equipment

Standard equipment that comes with the Rottler F10A Automatic Boring and Sleeving Machine:

- Block Clamp Arm – set of 2 (Part# 502-1-30)

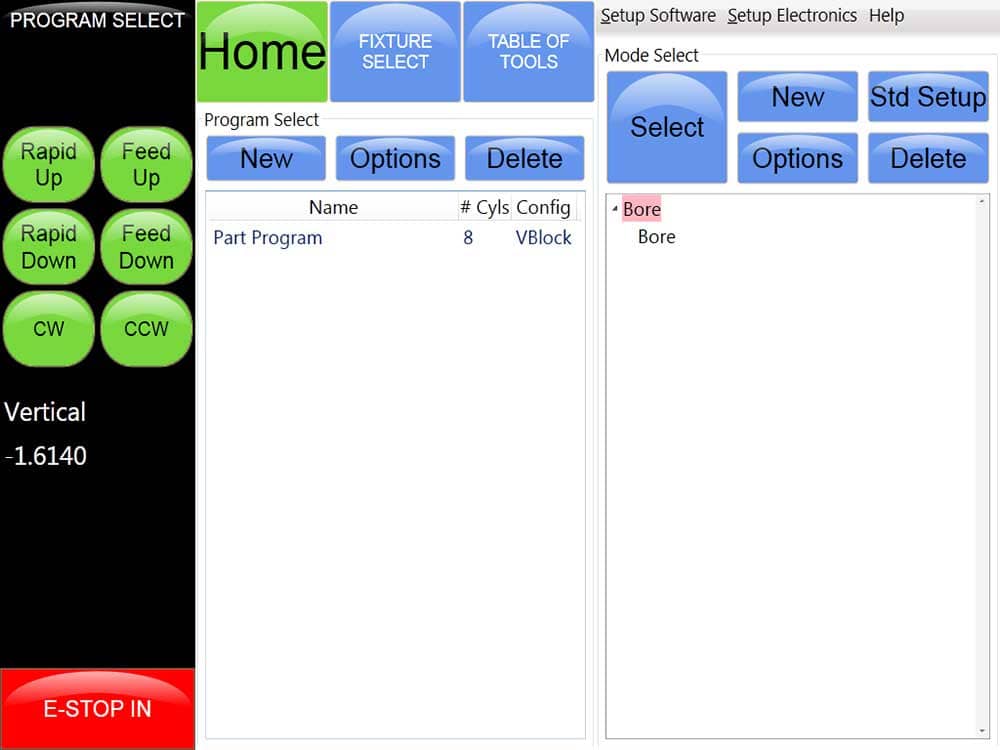

- CNC Touch Screen Control, Windows Operating System with Intel Processor

- Internet connection to the machine computer must be provided for training support and service.

- Automatic Vertical Cycles for Cylinder Boring, Resleeving and Counterboring

- Programming and Machine Operation thru extra bright touch screen.

- Electronic Handwheel for manual operation in .001″ (.01mm) or .005″ (.125mm) increments per Handwheel Detent

- Precision Digital Readout, .0001″ (.002mm) Resolution

- Spindle Travel by Precision Ball Screw & AC Servo Motor – Infinitely Variable

- Vertical Movement – Z Axis – Up and Down – 15″ (380mm)

- Spindle Rotation by AC Servo Motor – Infinitely Variable to 1200 RPM

- Machine Workhead Floats on Air Cushion for Precision Centering controlled from the Touch Screen – Total Travel – Left/Right Direction 50″ 1270mm

- Heavy Duty Spindle 3.25″ (82.5mm) Diameter with Inner Precision Angular Contact Bearings supported in Adjustable Outer Bearings

- Quick Change Cutterhead System

Give us a call, we have all the answers for you.

Rottler F10A specifications

| Control | Automatic CNC |

| Touch Screen | 114mm |

| Machine Height | 2032mm |

| Table - Size | 1370 x 530mm |

| Travel - Spindle Nose to Table | 670mm |

| Spindle - Rotation Speed | 100 to 1200 RPM |

| Spindle - Motor | 3.3 HP 2.5kW HP |

| Bore Capacity (with Optional Cutterheads) | 38 - 228mm |

| Feed per Revolution | Programmable Feed Rates .025 - .300mm |

| Spindle Travel (Vertical) | 381mm |

| Workhead Travel (Horizontal) | 1270mm |

| Dimensions - Machine | 1143D x 1549W x 2032mm H |

| Dimensions - Floor Space Requirements | 1170D x 1625Wmm |

| Dimensions - Shipping | 1854D x 2362W x 2362mm H |

| Machine Weight | 2042 kg |

| Electrical Requirements | 208-240V, 30A, 50/60Hz, 1Ph |

| Air Requirements | 28 l/min @ 6 bar |

| Paint Color Code | RAL9002 (Grey White) |

| Dimensions - Floor Space Requirements | 2565D x 3708Wmm |

| Dimensions - Shipping | 2286D x 3073W x 2794mm H |

| Machine Weight | 5546 kg |

| Electrical Requirements | 208-240V, 60A, 50/60Hz, 3Ph |

| Air Requirements | 6 l/min @ X bar |

| Paint Color Code | RAL9002 (Grey White) |

Control

Introducing the F10A Boring Bar: Advanced CNC Control and Precise Manual Operation

The F10A Boring Bar sets new standards in precision and convenience. Powered by a Windows Operating System with an Intel Processor, this machine features a user-friendly CNC Touch Screen Control. Experience seamless programming and operation, while benefiting from instant internet support directly from the machine.

Enhancing versatility, the F10A offers manual operation with two modes using the electronic handwheel. In coarse mode, each “click” moves the machine precisely by 0,01mm, while fine mode enables movements of 0,002mm per click. Moreover, the pulse handwheel allows feeding at 0,002mm or 0,01mm per click, providing fine control over machining processes.

Stay informed with the LED display, which accurately reads the vertical position in increments of 0,002mm. The F10A Boring Bar guarantees exceptional precision and control, empowering you to achieve superior results in your machining projects.